Need a mobile solution for site work? Our LTMC-30A Combined Portable Busbar Machine offers versatile Cutting, Punching, and Bending for Copper & Aluminium busbars. This 3-in-1 compact workstation is designed for Indian contractors and panel maintenance, allowing easy transport between sites. Features powerful hydraulic tools and a durable mobile cart. Contact us for the best Portable Busbar Machine Price in India today.

LTMC-30A Portable 3-in-1 Busbar Machine Combo

Product Overview (Mobile Workstation):

Introduction:

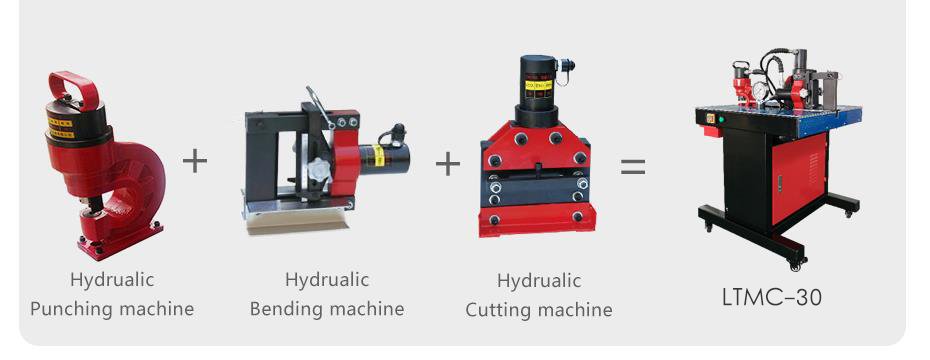

The LTMC-30A Portable Busbar Machine is a compact 3-in-1 combo unit designed for on-site busbar fabrication in India. It integrates three independent hydraulic tools: Punching, Shearing (Cutting), and Bending.

Specifically built for processing Copper and Aluminium busbars (Copper Patti), it is the perfect solution for contractors working on construction sites or maintaining electrical panels.

Processing Capabilities:

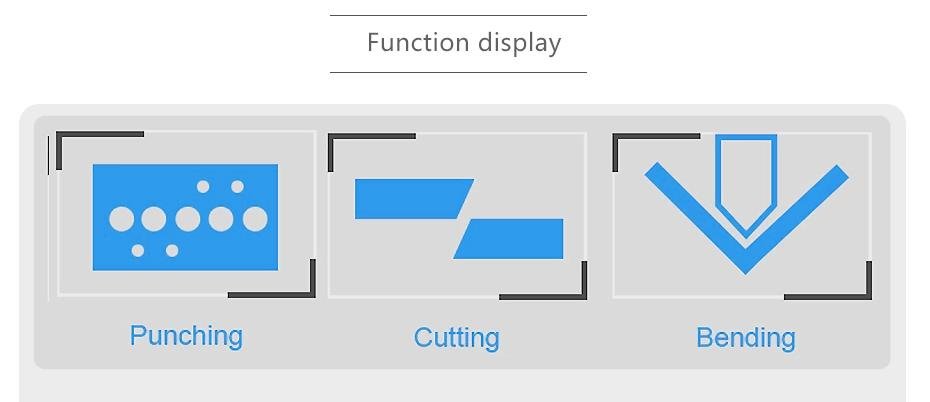

PUNCHING / CUTTING / BENDING

• Max. Processing Width: 150mm

• Max. Processing Thickness: 10mm

Product Application in India:

The machine operates on a standard Single-phase 220V power supply, making it highly versatile for any location. It is widely used for:

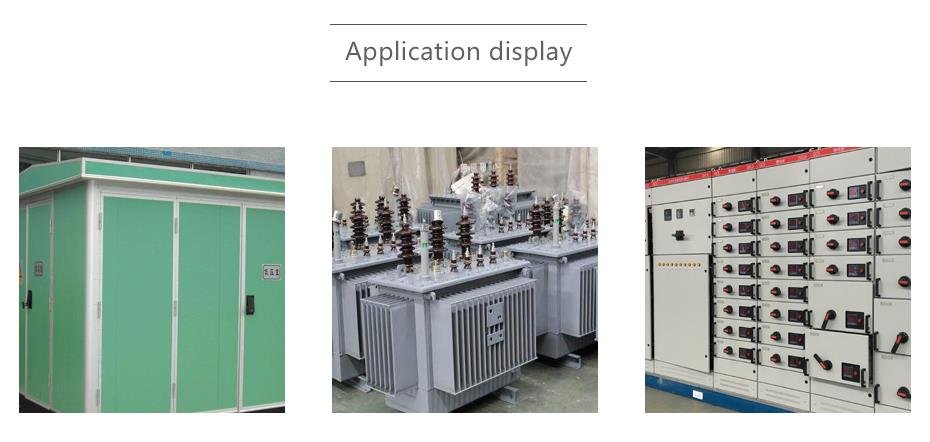

Suitable for industries including High and Low Voltage Switchgear, Substations, Busway/Busduct systems, Shipbuilding, Elevator manufacturing, and general Chassis fabrication. It is the most suitable tool for making large electric control boxes directly at the project construction site.

Single Processing Units (Detachable):

Why Choose Us?

Our Factory & Service:

• Professional engineers to guide you from selection to operation.

• Guaranteed product quality with robust hydraulic components.

Global Partners:

Trusted by industry leaders like ABB, Siemens, Schneider, and EDK.

Our Global Reach:

Our products are exported to over 100 countries, including the USA, UK, Germany, Russia, Canada, Australia, Brazil, Vietnam, Saudi Arabia, and many more.

Due to superior performance, powerful functions, and stable quality, we have won unanimous praise from customers globally.

Technical Specifications:

| Item | Model |

| LTMC-30A | |

| Rated Oil Pressure (kn) | 630 |

| Max. Processing Width (mm) | 150 |

| Max. Processing Thickness (mm) | 10 |

| Out Dimension (mm) | 700×700×1100 (Compact) |

| Diameter of Standard Dies (mm) | ¢10.5, ¢13.8, ¢17, ¢20.5 |

| Input Voltage | 220V / 50HZ (Single Phase) |

| Container Size (mm) | 990×760×1320 |

| Machine Weight (kg) | 165 |

Hot Tags (India): Portable 3 in 1 busbar machine price India, LTMC-30A combined busbar machine,

Hot Tags: mobile busbar processing machine, hydraulic busbar cutting punching bending machine, portable busbar bender, copper patti cutting machine, aluminium busbar fabrication tool, site work busbar machine, portable hydraulic pump for busbar, small busbar machine for contractors, busbar machine manufacturers China, factory price.

FAQ – LTMC-30A Portable Busbar Machine for Indian Customers

1. What is the main use of the LTMC-30A busbar machine?

The LTMC-30A is a 3-in-1 Combo machine that integrates Punching, Shearing (Cutting), and Bending functions. It is specifically designed for processing Copper and Aluminium busbars on construction sites or in small workshops.

2. What is the maximum busbar size it can handle?

It can process busbars up to 150mm in width and 10mm in thickness, covering most standard sizes used in distribution panels.

3. What power supply is required?

This machine runs on a standard Single-Phase 220V/50HZ power supply. This is a huge advantage for site work where 3-phase power might not be available.

4. Is the machine portable?

Yes. With compact dimensions (700×700×1100mm), a weight of 165kg, and heavy-duty casters, it is easy to move around the job site or transport in a vehicle.

5. Does it come with punching dies?

Yes, it includes standard die sets for hole diameters: ¢10.5, ¢13.8, ¢17, and ¢20.5 mm.

6. How do I switch between functions?

The machine features a hydraulic selector valve or quick couplers, allowing you to easily switch between the Punching, Cutting, and Bending tools.

7. What industries use this machine?

It is ideal for Electrical Contractors, Panel Builders (Switchgear & Controlgear), Substation maintenance, Elevator manufacturing, and Shipbuilding.

Industry Keywords (India Market):

Portable busbar machine India, mobile busbar processing machine, 3 in 1 busbar combo, hydraulic busbar tools set, portable copper busbar bender, busbar cutting machine for site, busbar punching machine portable, manual busbar machine price, LTMC-30A busbar machine, busbar machine for electrical contractors, small busbar bending machine, aluminium busbar processing tool, copper patti machine, busbar fabrication equipment on wheels, single phase busbar machine, hydraulic electric pump for busbar tools.