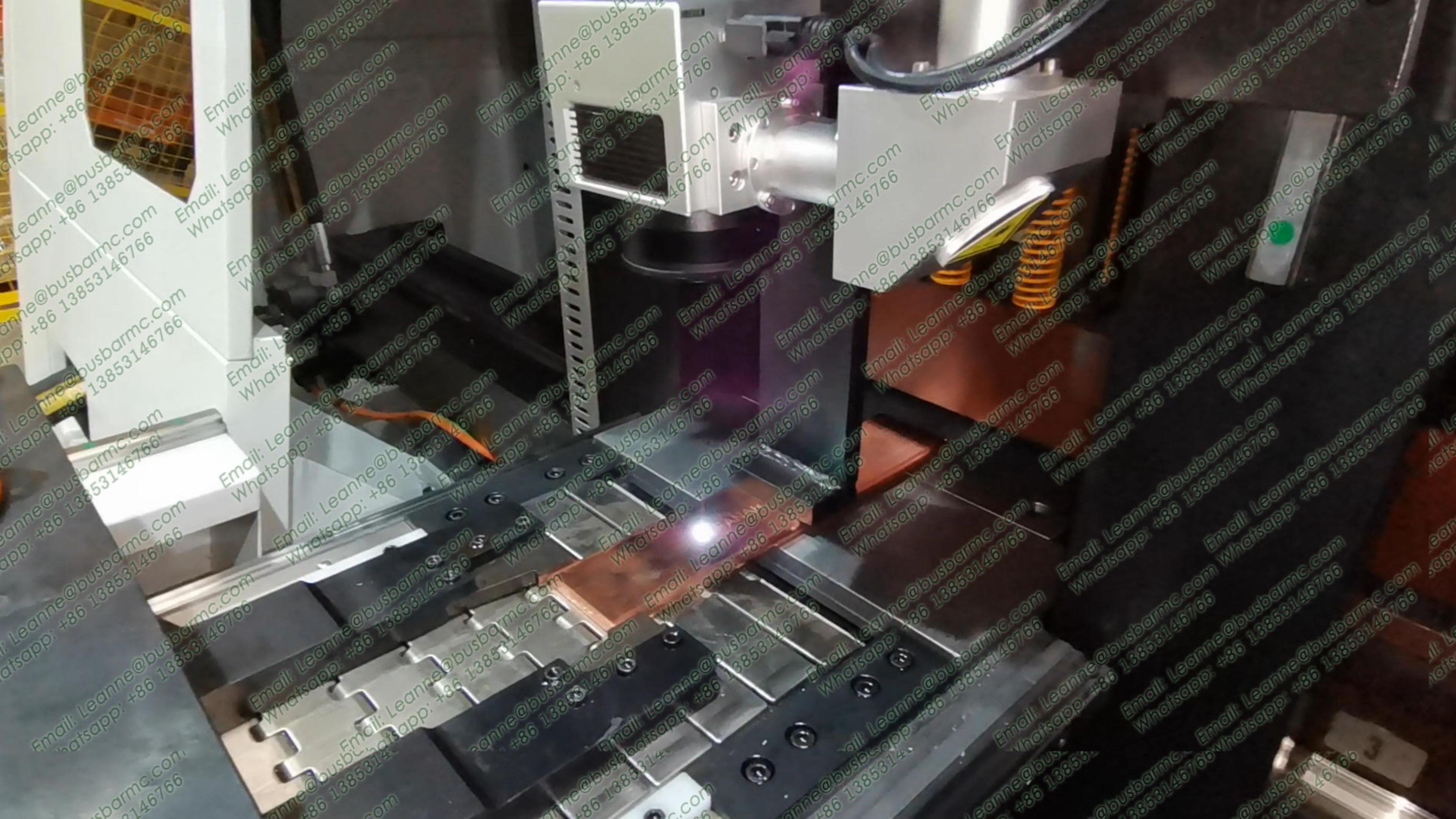

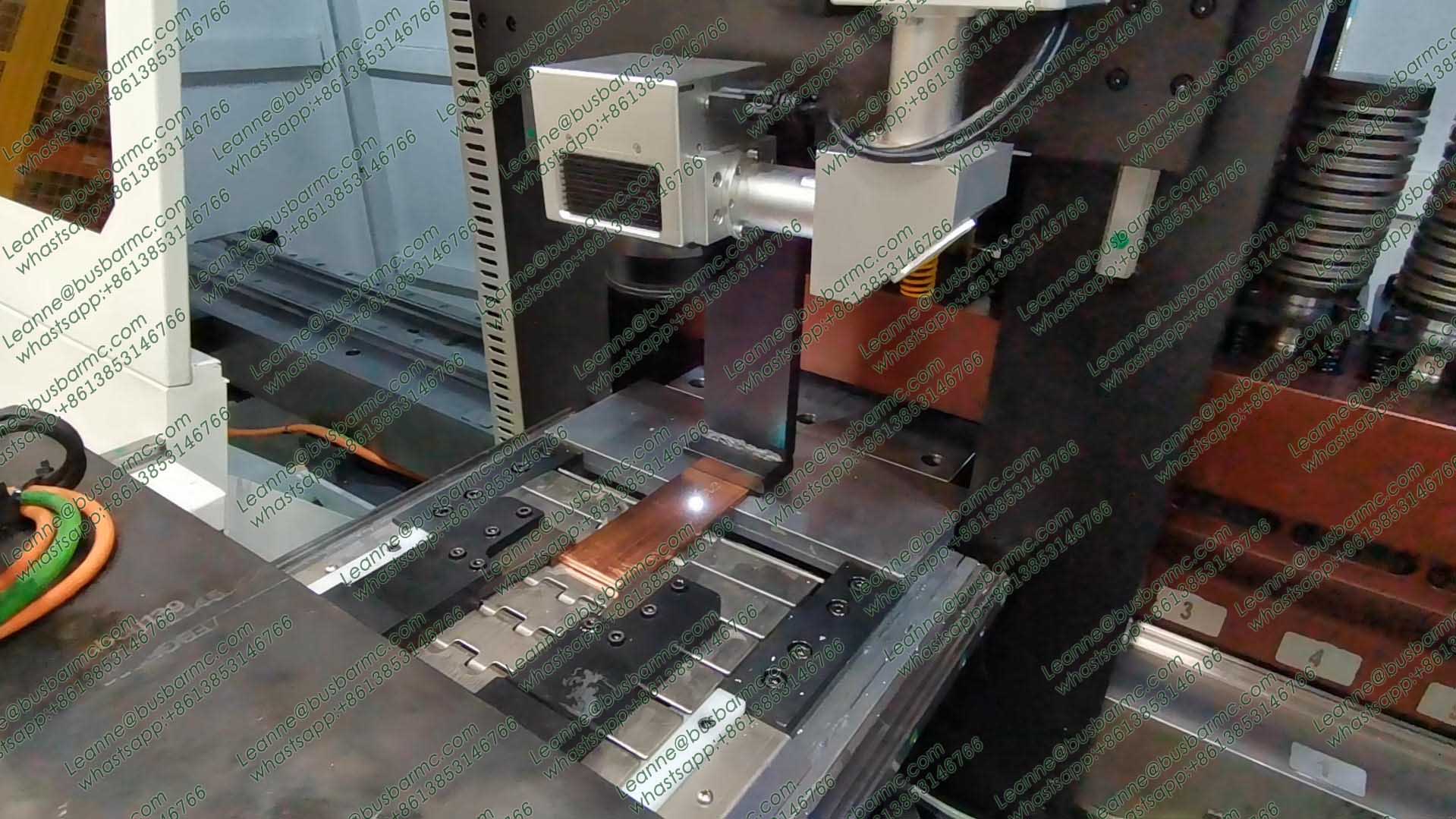

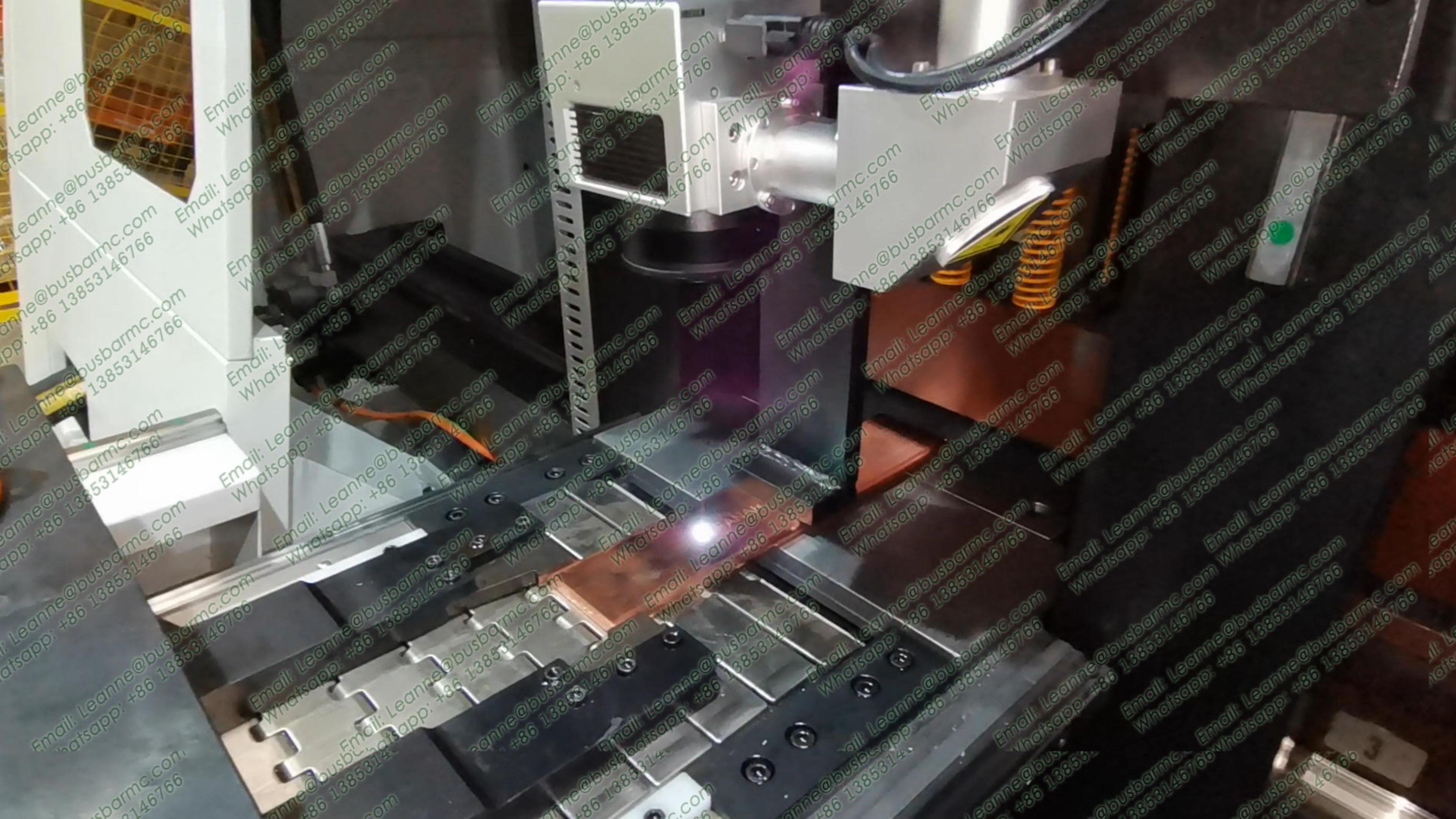

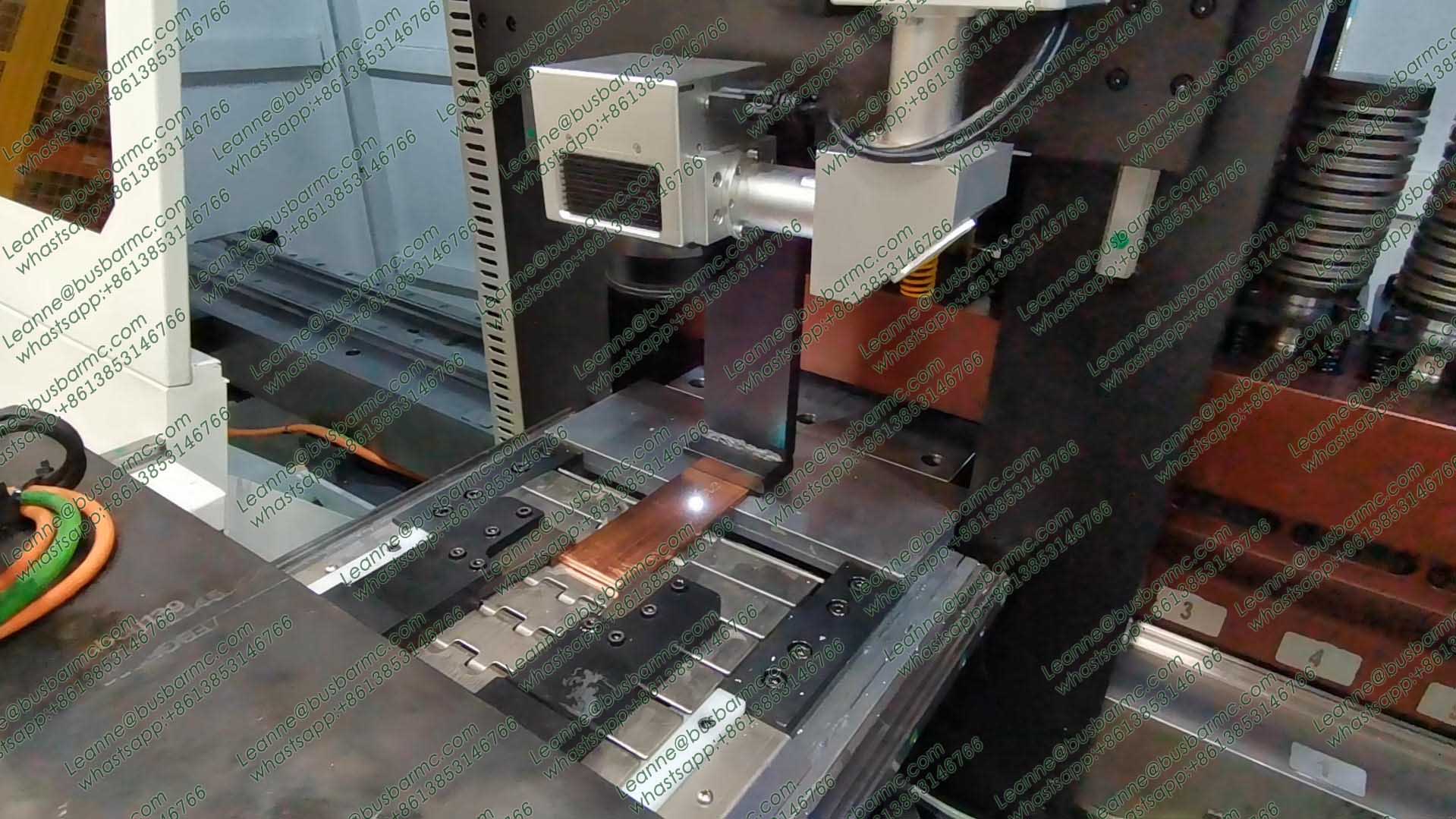

Looking for a reliable identification solution for your busbars? Our Automatic Copper Busbar Marking Machine provides high-precision Embossing and Coding for both Copper and Aluminium. Designed for Indian panel builders, this machine ensures deep, permanent marking for Phase, Neutral, and Earth identification. Boost your production quality with clear lettering and heavy-duty performance. Contact us now to get the best Busbar Marking Machine Price in India.

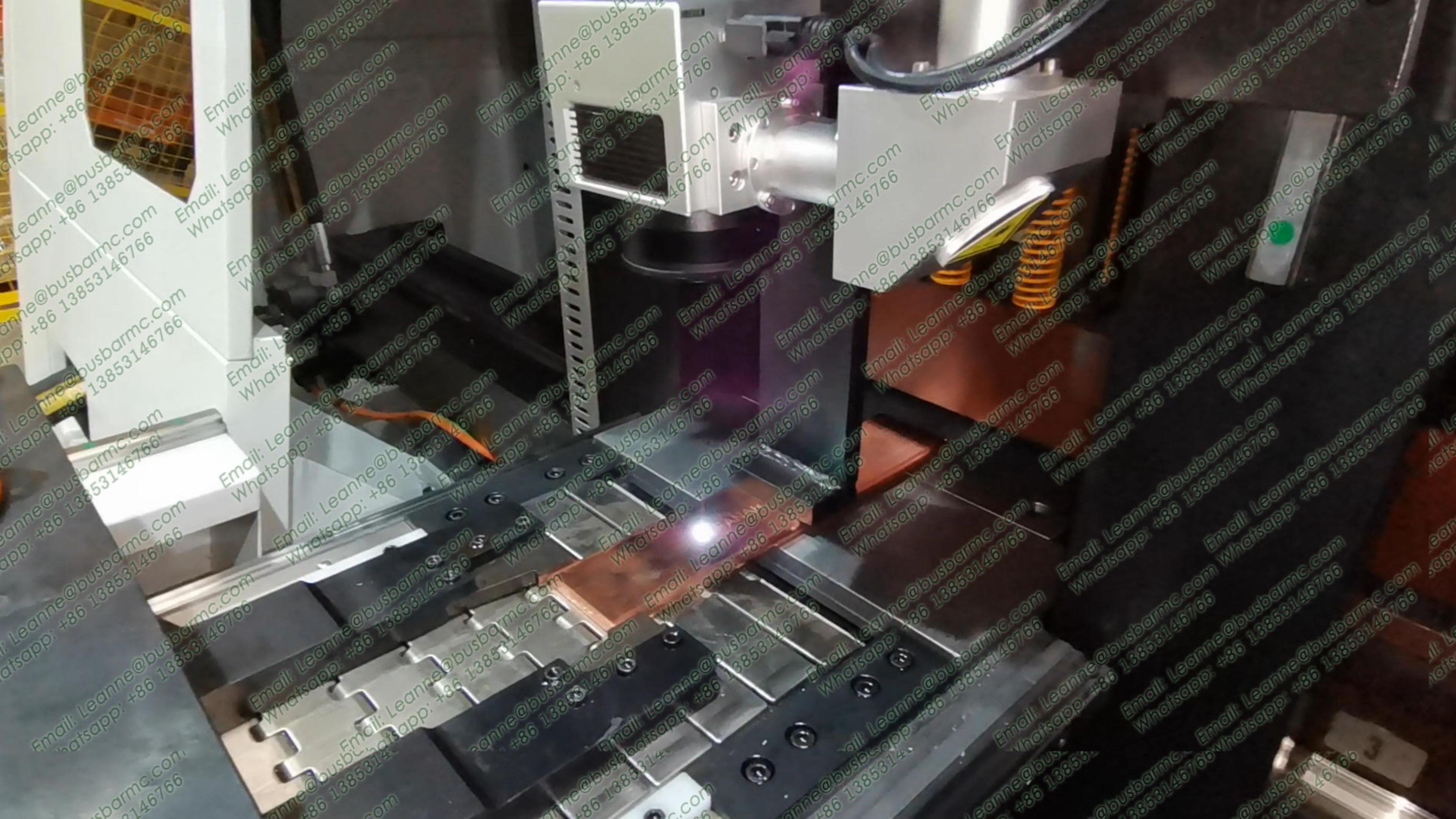

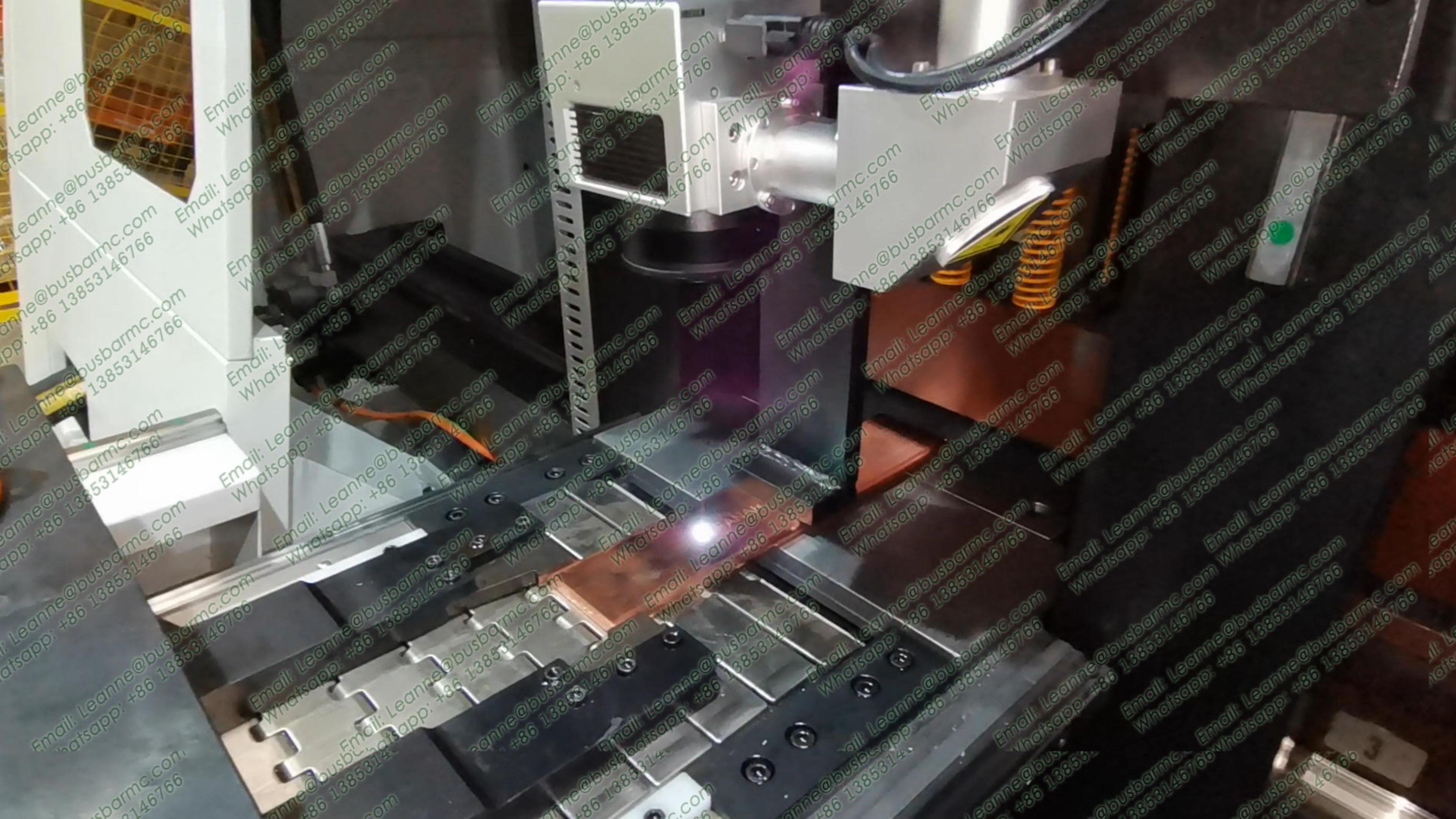

Automatic Copper Busbar Laser Marking Machine for Indian Panel Builders

Upgrade your switchgear assembly line with the Copper Busbar Laser Marking Machine, specifically engineered for the Indian electrical industry. This machine delivers fast, clear, and permanent coding on copper and aluminium busbars, essential for Phase Identification (R-Y-B) and branding.

This professional fiber laser marking system ensures high precision, stable performance, and long-lasting engraving results. It is widely used by top manufacturers of PCC/MCC Panels, electrical switchgear, power distribution cabinets, transformer manufacturing, and APFC panels across India.

High-speed fiber laser marking engine, optimized for both Copper and Aluminium busbars.

Permanent and clear engraving for ISI marks, Company Logos, Serial Numbers, QR codes, and Technical Specs.

Suitable for 3–15 mm thick busbars (Standard Indian Specs).

Non-contact processing: Ensures no deformation or burn marks on your costly copper material.

Supports automation: Easily integrates into existing CNC busbar production lines or cutting/punching centers.

Low maintenance design for dusty industrial environments and long service life.

Copper & Aluminium busbar processing centers.

LT & HT Switchgear production (Low Tension / High Tension).

Power distribution cabinet (PCC) & Motor Control Center (MCC) manufacturing.

Transformer & electrical component plants (CT/PT manufacturing).

If you need customized busbar laser marking solutions or price details in INR, feel free to contact us anytime!

LT Busbar Machine Demo Video:

| Item | Specification |

| Laser Type | Fiber Laser Marking System |

| Laser Power | 50W / 100W / 200W Optional |

| Wavelength | 1064 nm |

| Marking Speed | Up to 8000 mm/s |

| Modulation Frequency Range | 20kz~80kHz (Adjustable) |

| Marking Area | 110×110 mm / 200×200 mm / 300×300 mm Optional |

| Applicable Materials | Copper Busbar, Aluminum Busbar, Stainless Steel, Metal Plates |

| Busbar Thickness | 3 – 15 mm |

| Cooling System | Air Cooling |

| Control System | PC Control with Professional Laser Software |

| Power Supply | AC 110V / 220V, 50/60Hz |

| Working Mode | Automatic / Manual |

| Service Life of Laser Source | ≥ 100,000 Hours |

Q1: What materials can this laser marking machine handle?

This machine is specially designed for Copper and Aluminium busbars commonly used in LT/HT panels. It can also mark stainless steel nameplates and other metal components.

Q2: Is the laser marking permanent for ISI/IEC standards?

Yes. The Fiber laser technology creates permanent, deep, and wear-resistant marks. It is ideal for marking Phase (R, Y, B), Neutral, Earth, and technical ratings that will not fade over time.

Q3: Can this machine be integrated with my existing busbar line?

Yes. It fully supports automation and can be integrated with CNC busbar punching, bending, and cutting machines to create a fully automatic busbar processing center.

Q4: What contents can be marked on the busbar?

It supports alphanumeric text, serial numbers, QR codes, barcodes, Company Logos, dates, and batch numbers for full traceability in switchgear assembly.

Q5: Will laser marking damage the conductivity of the copper busbar?

No. Laser marking is a non-contact process with no mechanical force. It causes no deformation and ensures the electrical conductivity remains intact.

Q6: What laser power is best for busbar production?

20W or 30W is suitable for most surface marking. However, for deep engraving required by some Indian PSUs or export quality panels, 50W or 100W is recommended.

Q7: Is daily maintenance complicated?

No. The fiber laser system requires very low maintenance, has no consumables (like ink), and offers a long service life of over 100,000 hours.

Q8: Do you provide service in India?

Yes. We support customized marking solutions and provide remote and on-site support for installation and training for Indian customers.

Busbar Marking Machine India, Laser Engraving for Electrical Panels, Copper Busbar Identification System, Aluminium Busbar Coding Machine, Switchgear Manufacturing Machines, Busbar Processing Equipment, Fiber Laser Marker 50W

Copper busbar laser marking machine, busbar marking machine price in India, automatic busbar identification system, aluminium busbar etching machine, laser marker for copper patti, busbar punching and marking machine, fiber laser marking machine for electrical panels, busbar coding machine, R Y B phase marking machine, heavy duty busbar marking machine, CNC busbar processing center with marking, laser engraving machine for switchgear, LT HT panel busbar marking, busbar lettering machine, marking machine for power distribution cabinet, busbar numbering machine, electrical busbar engraving tool, copper flat laser marking, busbar manufacturing plant machinery, high speed busbar marker, non-contact busbar marking, busbar branding machine, automatic laser marker for copper flats, panel board manufacturing machines India, busbar fabrication machinery, laser marking system for aluminium conductors, permanent marking on copper busbar, industrial laser marker for busbars.