Looking for an economic busbar fabrication solution? Our 303U-3-C Manual Hydraulic Busbar Processing Machine is a robust 3-in-1 workstation for Cutting, Punching, and Bending. Designed for Indian Switchgear & Panel Builders, it processes Copper and Aluminium busbars efficiently with three independent units. Simple button operation, low maintenance, and high durability. Contact us today for the best Manual Busbar Machine Price in India.

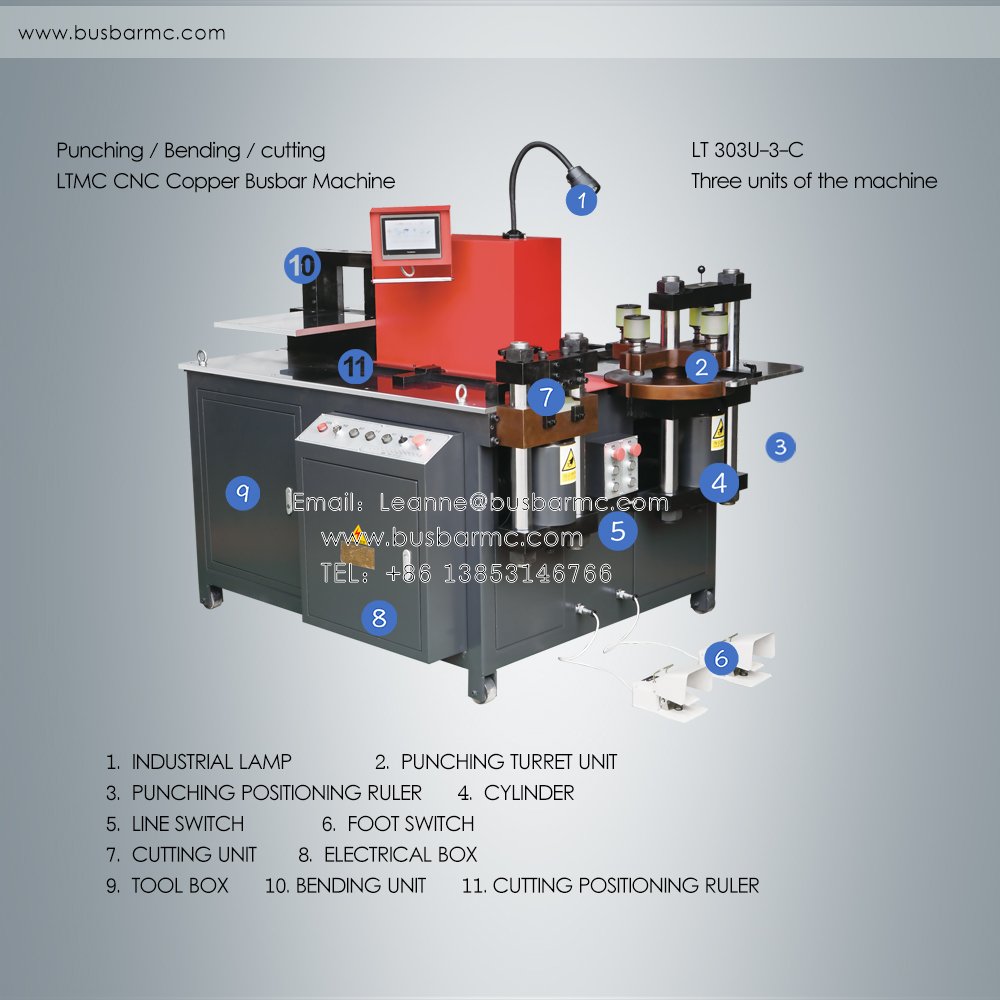

303U-3-C Manual Hydraulic Busbar Processing Machine (3-in-1)

Copper Busbar Bending Machine for Indian Panel Builders

This 303U-3-C series Manual Hydraulic Busbar Processing Machine is a versatile 3-in-1 workstation featuring three independent units: Punching, Shearing (Cutting), and Bending.

Designed for the Indian electrical industry, the three units can be operated simultaneously or sequentially. The working stroke of each unit is easily adjustable, reducing processing time and boosting efficiency for Copper and Aluminium busbar fabrication (Copper Patti & Aluminium Flats).

Technical Parameters:

Item | Model |

303U-3-C | |

Nominal force (kn) | 300 |

Punching dia. range (mm) | ф4.3~ф25 |

Max.thickness (mm) | 12 |

Max.width (mm) | 150 |

Max.shearing thickness (mm) | 12 |

Max.shearing width (mm) | 150 |

Max.horizontal bending width (mm) | 150 |

Max.horizontal bending thickness (mm) | 12 |

Max.vertical bending size (mm) | 10×100 |

Power (kw) | 1×4KW |

Table size (mm) | 1650×1050 |

Outside dimension (mm) | 1720×1220×1220 |

Container size (mm) | 1800×1300×1430 |

Total weight (kg) | 1220KG |

Main Features:

1. Shearing Unit: Uses a vertical processing mode with a flat blade. The cut interface is flat, ensuring no waste, no burrs, and no droop, saving expensive Copper material.

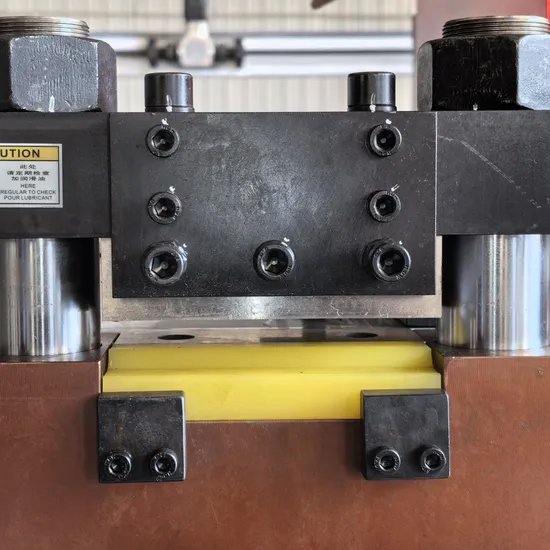

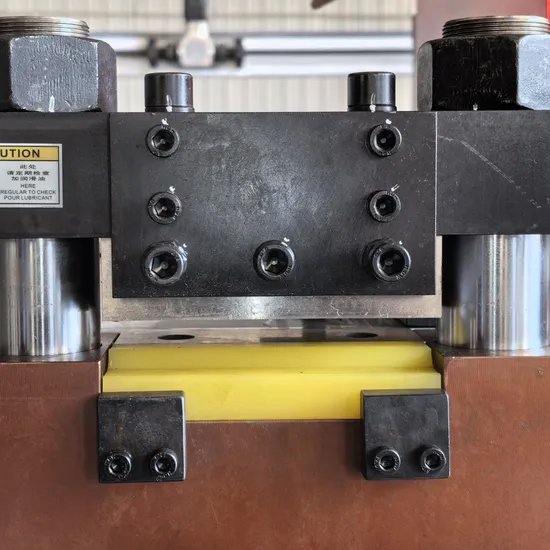

2. Punching Unit: Equipped with a six-mode Turret Turnplate in tooth shape. This provides a clear view and eliminates the need for frequent die changes, making operation simple and efficient.

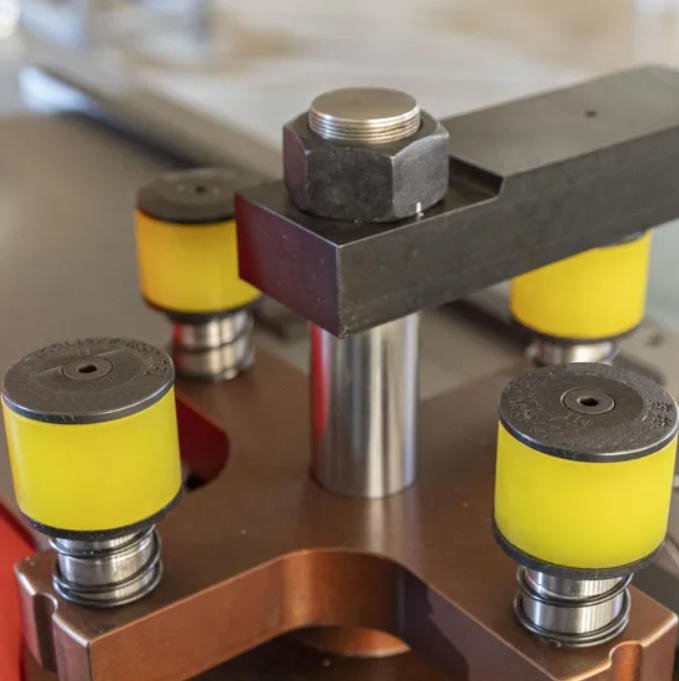

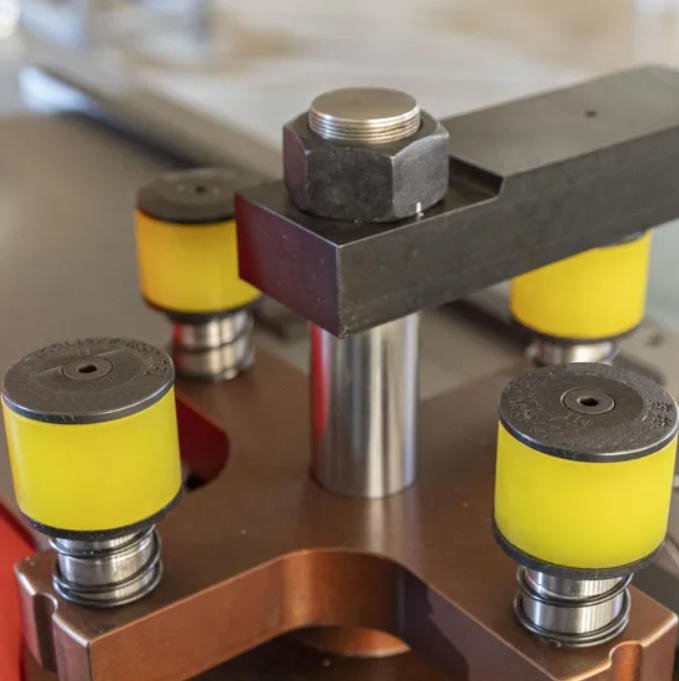

3. Bending Unit: Adopts a horizontal bending structure. By changing molds, it can perform Flat Bending (Horizontal) and Vertical Bending.

4. Multifunction: Capable of Embossing, Flattening, Twisting, and Cable End Crimping by simply changing the tooling dies.

5. Mobility: Features four heavy-duty casters, making it easy to move around your workshop or factory floor.

6. Customization: We can install custom molds or tools to meet specific user requirements for special shape processing.

Product Details Display:

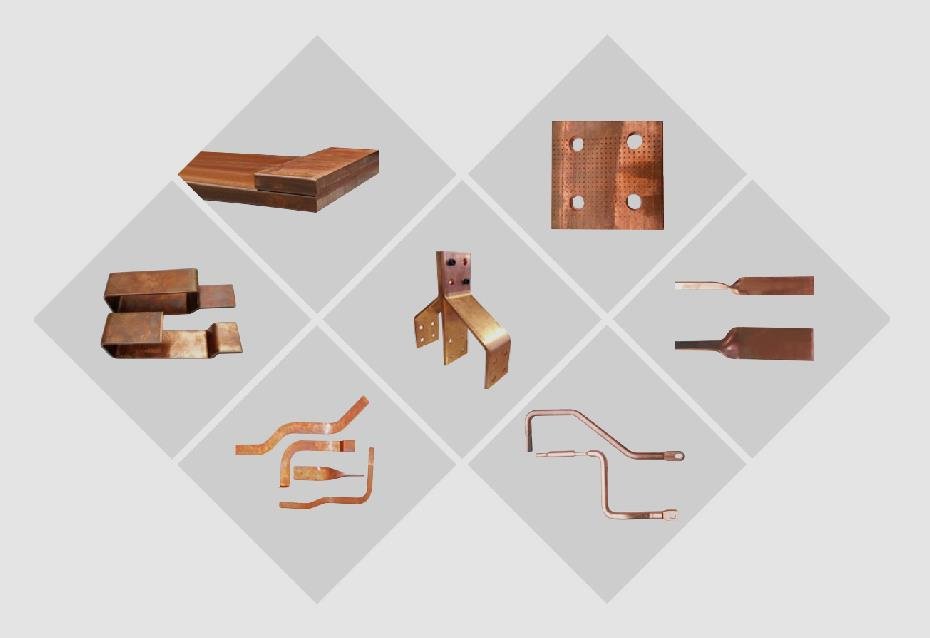

Processing Samples:

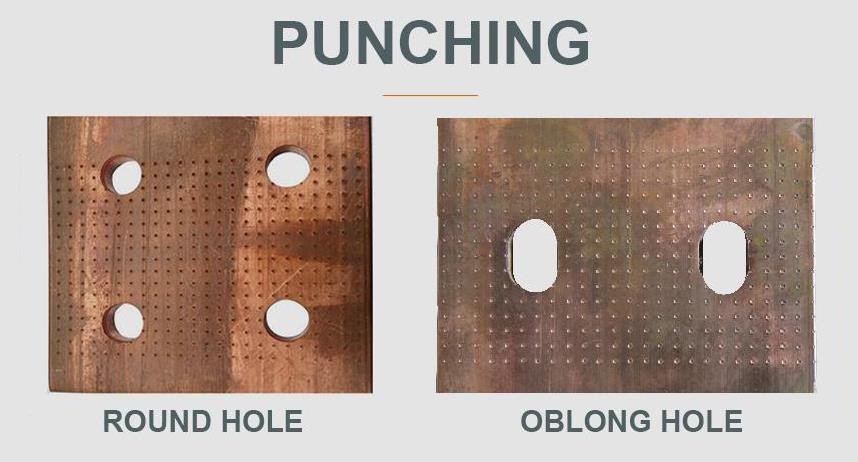

Punching Samples

Capable of punching Round holes and Oblong (Oval) holes using the turret punching unit.

Cutting Samples

The cutting unit ensures a flat interface with no waste, no burr, and no droop.

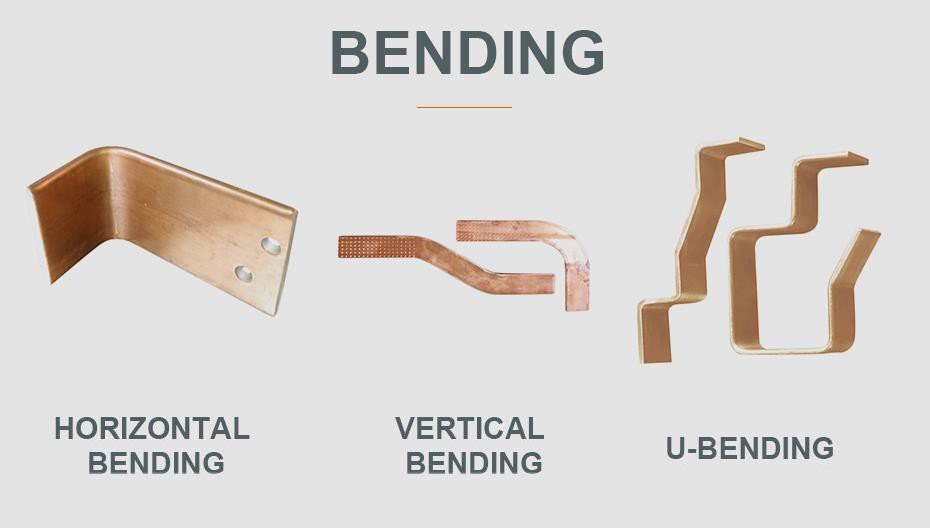

Bending Samples

The closed integral frame structure allows for Flat Bending, Vertical Bending, and U-Bending.

Other Special Processing

Our Factory

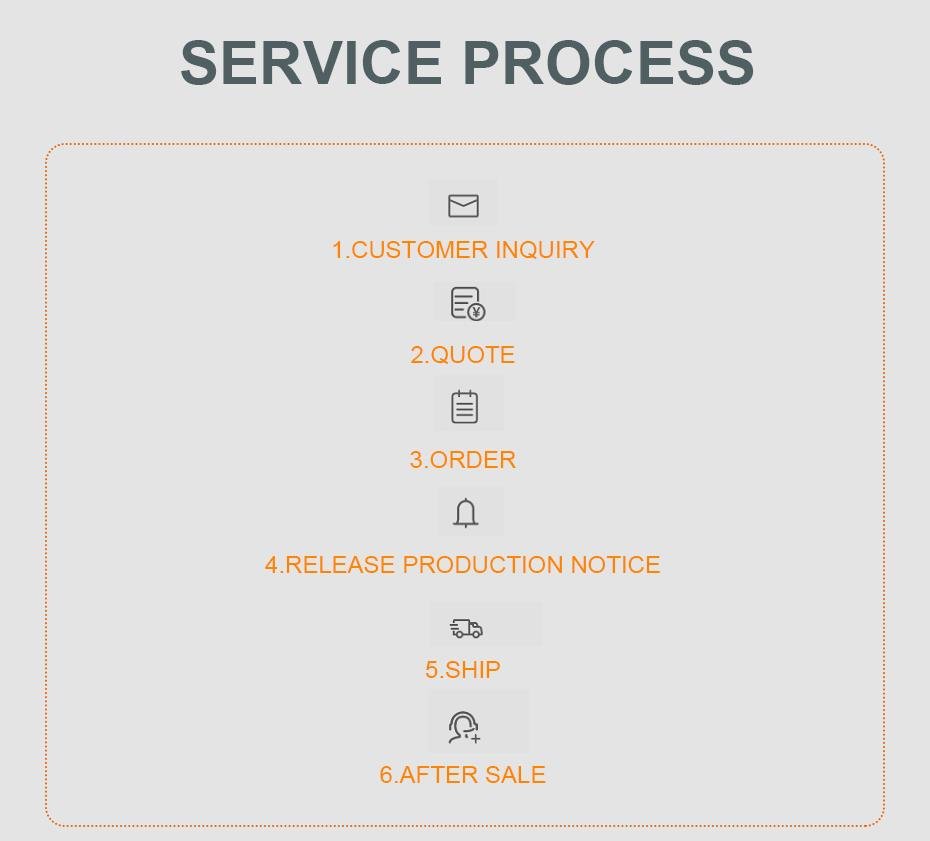

Our Service Process

Customer Inquiry - Quote - Order - Production - Shipping - After-Sales Service

Our engineers conduct regular return visits to ensure customer satisfaction and improve product quality for the Indian market.

Package & Delivery

We use waterproof plastic film inside and sturdy wooden cases outside for safe sea freight to India.

Our Global Clients

LTMC Company specializes in busbar processing equipment, sold in over 100 countries including the USA, UK, Germany, Russia, Australia, Brazil, Vietnam, Saudi Arabia, and extensively in India.

Hot Tags (India): 303U-3-C manual hydraulic busbar machine price India, 3 in 1 busbar processing machine,

Hot Tags: 3 station busbar machine, copper busbar bending machine, busbar punching machine, busbar cutting machine, manual busbar bender, hydraulic busbar press, combined busbar machine, busbar fabrication machine for panels, switchgear manufacturing machines, busbar machine manufacturers China, factory price.

Manual Busbar Machine Demo Video:

Q1: What materials can the 303U-3-C process?

A1: It is designed for processing Copper and Aluminium busbars (Copper Patti & Aluminium Flats) commonly used in Indian electrical panels.

Q2: What are the maximum processing dimensions?

A2: It can handle busbars up to 12mm in thickness and 150mm in width for Punching, Cutting, and Bending.

Q3: How is the punching unit designed?

A3: It features a Six-mode Turret Turnplate, which eliminates frequent die changes and ensures precise punching of Round and Oblong holes.

Q4: Does the cutting unit produce waste?

A4: No. The vertical flat blade cutting mode ensures a smooth, burr-free interface with no scrap waste.

Q5: Can it perform different bending shapes?

A5: Yes. By changing molds, it supports Flat Bending, Vertical Bending, and U-Bending.

Q6: Is the machine portable?

A6: Yes, it is equipped with four heavy-duty casters for easy mobility on the factory floor.

Q7: What power supply is required?

A7: It operates on a 1×4KW motor. We can customize the voltage (e.g., 415V, 50Hz) for India.

Q8: What industries use this machine?

A8: Ideally suited for Electrical Switchgear Manufacturers, Control Panel Builders, and Power Distribution workshops.

Industry Keywords (India Market):

303U-3-C busbar machine, 3 in 1 manual hydraulic busbar machine, copper busbar bending machine India, busbar cutting punching bending machine, manual busbar bender price, aluminium busbar processing machine, hydraulic busbar press machine, non-CNC busbar machine, busbar fabrication equipment for panels, switchgear assembly tools, busbar punching machine turret type, flat bending busbar machine, vertical bending machine, U-bending busbar tool, cable end crimping machine, embossing busbar machine, industrial busbar machine, high voltage panel machine, low voltage busbar machine, busbar production equipment, copper aluminum busbar machine, busbar machinery suppliers India, busbar machine factory price.