Boost your switchgear production with our 303U-3 Hydraulic Busbar Processing Machine. This versatile 3-in-1 system offers simultaneous Cutting, Punching, and Bending for Copper & Aluminium busbars. Featuring three independent workstations, it ensures high efficiency for Panel Builders. Robust, reliable, and easy to operate. Contact us now to get the best Busbar Machine Price in India.

303U-3 Hydraulic Busbar Punching Shearing Bending Machine (3-in-1)

The LT-303U-3 Busbar Processing Machine is a versatile 3-in-1 hydraulic system designed for Indian Switchgear and Panel Builders.

This Single Working Table machine integrates three core functions: Punching, Bending, and Cutting (Shearing). It is capable of processing Copper and Aluminium busbars up to 12mm in thickness and 160mm in width, making it ideal for LT Panel fabrication.

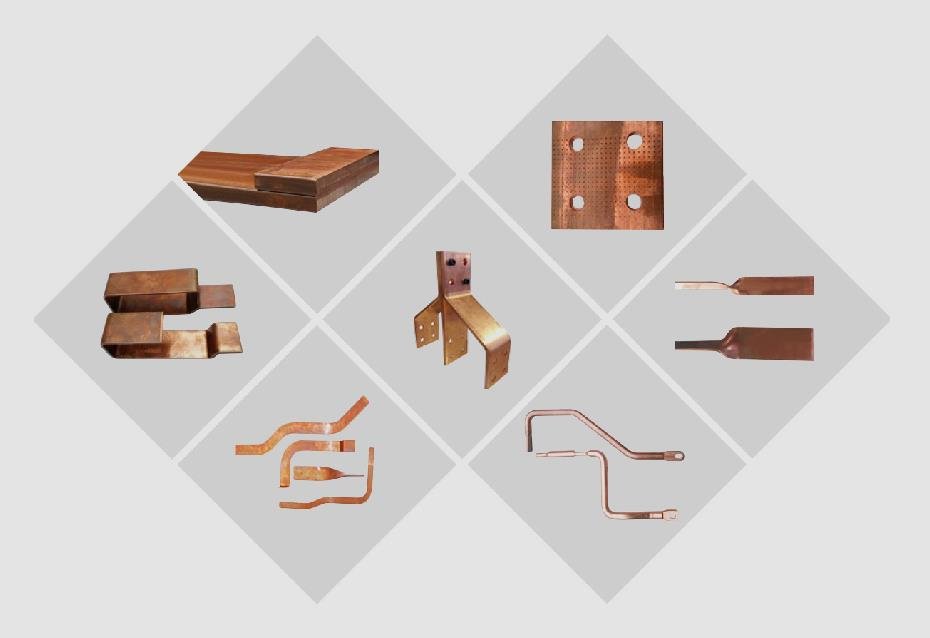

Processing Functions & Samples:

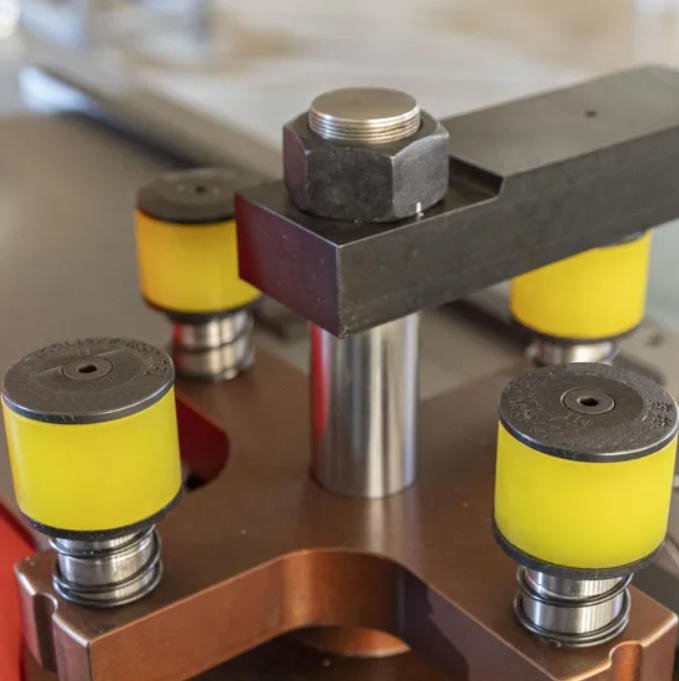

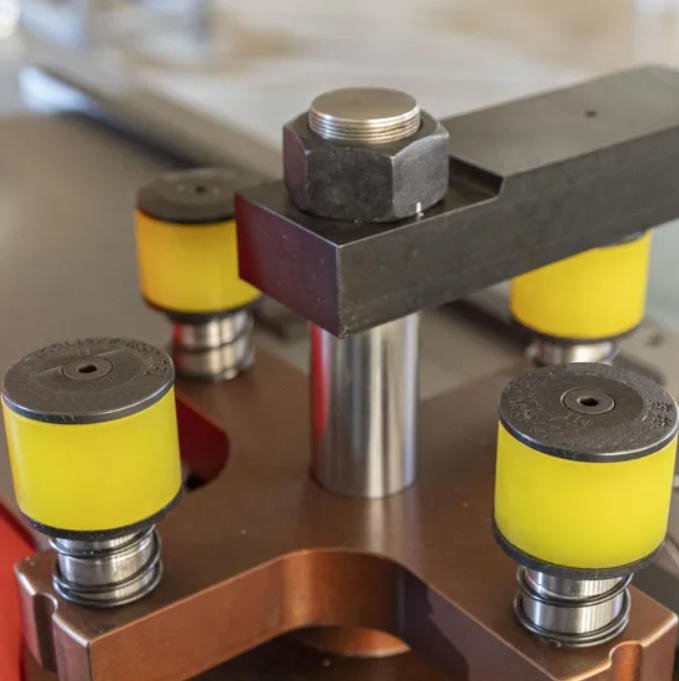

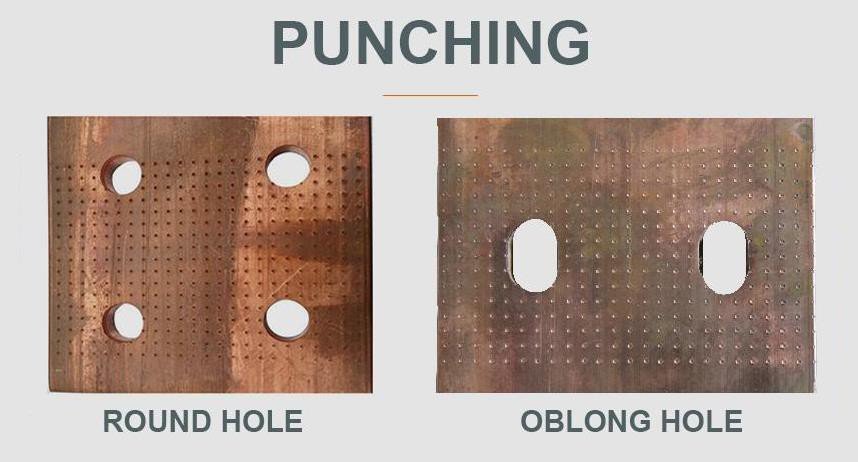

1. Punching Function:

Capable of punching Round holes, Oblong (Oval) holes, and Square holes. We provide standard dies suitable for M6, M8, M10, M12, M16 bolts used in Indian electrical standards.

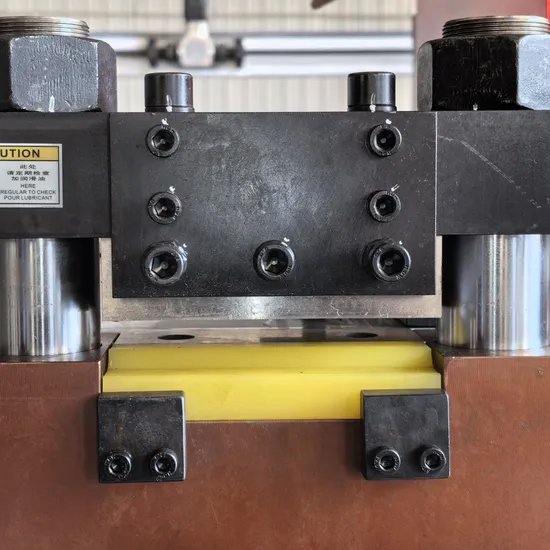

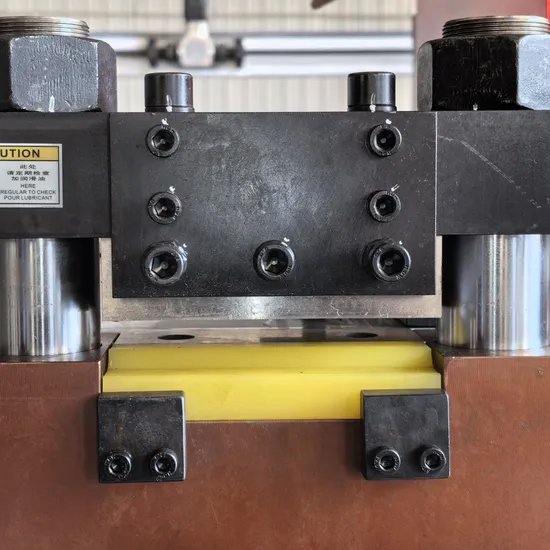

2. Cutting (Shearing) Function:

Uses a shearing method that ensures the cutting surface is flat, smooth, and burr-free. No waste of expensive Copper/Aluminium material.

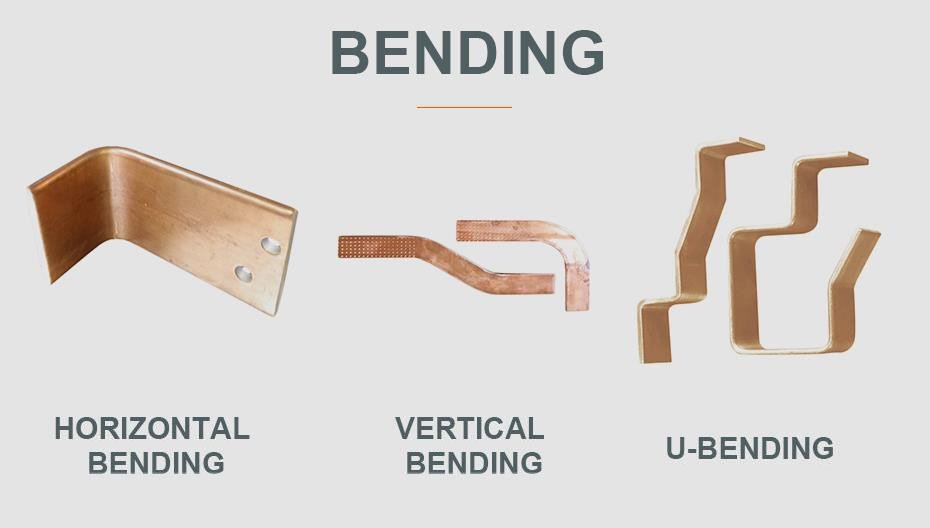

3. Bending Function:

Capable of performing Vertical Bending, Flat Bending, and U-Bending (for interconnecting busbars).

Other Special Functions:

By changing the molds, this machine can also perform Embossing, Twisting, and Cable Connector Crimping.

Our Service for India:

We are fully responsible for your after-sales service. If you have any problems, feel free to contact us.

You can consult us about machine operation, mold changing, or troubleshooting via Video Call (WhatsApp).

We have satisfied clients in more than 100 countries, including many Panel Builders in India.

Contact Me:

WhatsApp: +8613853146766

Skype: Leanne.Li88

Official Website: http://www.busbarmc.com/

E-mail: Leanne@busbarmc.com

Technical Parameters:

| Items | Model |

| 303U-3 | |

| Nominal force (kn) | 300 |

| Punching dia. range (mm) | ф4.3~ф25 |

| Max. thickness (mm) | 12 |

| Max. width (mm) | 160 |

| Max. shearing thickness (mm) | 12 |

| Max. shearing width (mm) | 160 |

| Max. horizontal bending width (mm) | 160 |

| Max. Horizontal bendind thickness (mm) | 12 |

| Max. vertical bending size (mm) | 10×100 |

| Power (kw) | 3×4KW |

| Bending precision (degree) | ±1° |

| Repeat bending precision (degree) | ±0.5° |

| First table size (mm) | 1650×1050 |

| Second table size (mm) | ----- |

| Outside dimension (mm) | 1720×1220×1240 |

| Container size(mm) | 1800×1300×1450 |

| Total weight(kg) | 1320KG |

Hot Tags (India): 303U-3 busbar punching shearing bending machine price, 3 in 1 copper busbar machine,

Hot Tags: cnc busbar machine, 3 in 1 busbar machine, busbar bending machine, busbar punching machine, busbar cutting machine, copper busbar bending machine, cnc bending machine, cnc punching machine, bending machine, busbar machine, copper busbar machine, cutter machine, machine bending, China, suppliers, manufacturers, factory, price, hydraulic busbar machine India.

LT Busbar Machine Demo Video:

1. What functions does the 303U-3 busbar machine offer?

The LT-303U-3 is a 3-in-1 machine that integrates Punching, Shearing (Cutting), and Bending functions. It is designed to process both Copper and Aluminium busbars efficiently for the Indian electrical industry.

2. What is the maximum processing capacity?

It can process busbars up to 12mm in thickness and 160mm in width. The max shearing thickness is 12mm, and it can perform vertical bending up to 10×100mm.

3. How precise is the bending?

The machine offers high bending precision of ±1° with a repeat precision of ±0.5°, ensuring consistent angles for switchgear panels.

4. What power supply is required?

The machine uses a powerful 3×4KW motor system. We can customize the voltage (e.g., 415V, 50Hz) to match Indian industrial standards.

5. Can it perform special processing?

Yes. By changing the molds/dies, the machine can perform Embossing, Twisting, Flattening, and Cable End Crimping.

6. Is the machine easy to move?

Yes, it is equipped with heavy-duty casters, making it portable within the workshop or construction site.

7. What after-sales support do you provide in India?

We provide comprehensive after-sales service, including video guidance for installation and troubleshooting via WhatsApp or Skype.

8. What industries is this machine suitable for?

It is ideal for LT/HT Switchgear manufacturers, Control Panel builders, Transformer factories, and Power Distribution projects in India.

Busbar Punching Shearing Bending Machine Price, 3 in 1 Busbar Machine India, Hydraulic Busbar Cutter Puncher Bender, Copper Patti Cutting Machine, Aluminium Busbar Processing Machine

Industry Keywords: 303U-3 busbar machine, copper busbar bending machine India, busbar cutting machine no waste, busbar punching machine round hole, hydraulic busbar machine 3 station, manual busbar machine price, electrical busbar processing machine, busbar fabrication machine for panels, flat bending busbar machine, vertical bending machine, U-bending busbar tool, cable end crimping machine, embossing busbar machine, industrial busbar machine, high voltage panel machine, low voltage busbar machine, busbar production equipment, copper aluminum busbar machine, busbar machinery suppliers India, CNC bending punching cutting machine, switchgear assembly tools, busbar processing tools, custom busbar machine.