Looking for a cost-effective busbar processing solution? Our 303U-3-C 3-in-1 Manual Hydraulic Busbar Machine offers precise Cutting, Punching, and Bending for Copper & Aluminium. Designed for Indian panel builders, this robust machine features three independent stations for simultaneous operation. Simple to operate and easy to maintain. Contact us today for the best Manual Busbar Machine Price in India.

303U-3-C 3-in-1 Manual Hydraulic Busbar Machine (Copper & Aluminium)

This series of 3-in-1 Manual Hydraulic Busbar Processing Machine features three independent processing units: Punching, Shearing (Cutting), and Bending. Specifically designed for Indian Panel Builders, the three units can be operated simultaneously or sequentially. The working stroke of each unit is easily adjustable, significantly reducing processing time and improving production efficiency for switchgear assembly. Its primary function is processing Copper and Aluminium busbars.

Equipped with three versatile stations, this machine is operated via manual buttons or a heavy-duty Foot Switch. Operators can easily Punch, Cut, and Bend busbars separately. It is the ideal production equipment for the High and Low Voltage (HT/LT) electrical industry in India.

Designed with reference to advanced international technology and adapted for robust usage conditions, this auxiliary equipment ensures high work efficiency and operational safety. It is most suitable for construction sites, large-scale electric control box manufacturing, and power transmission & distribution projects across India.

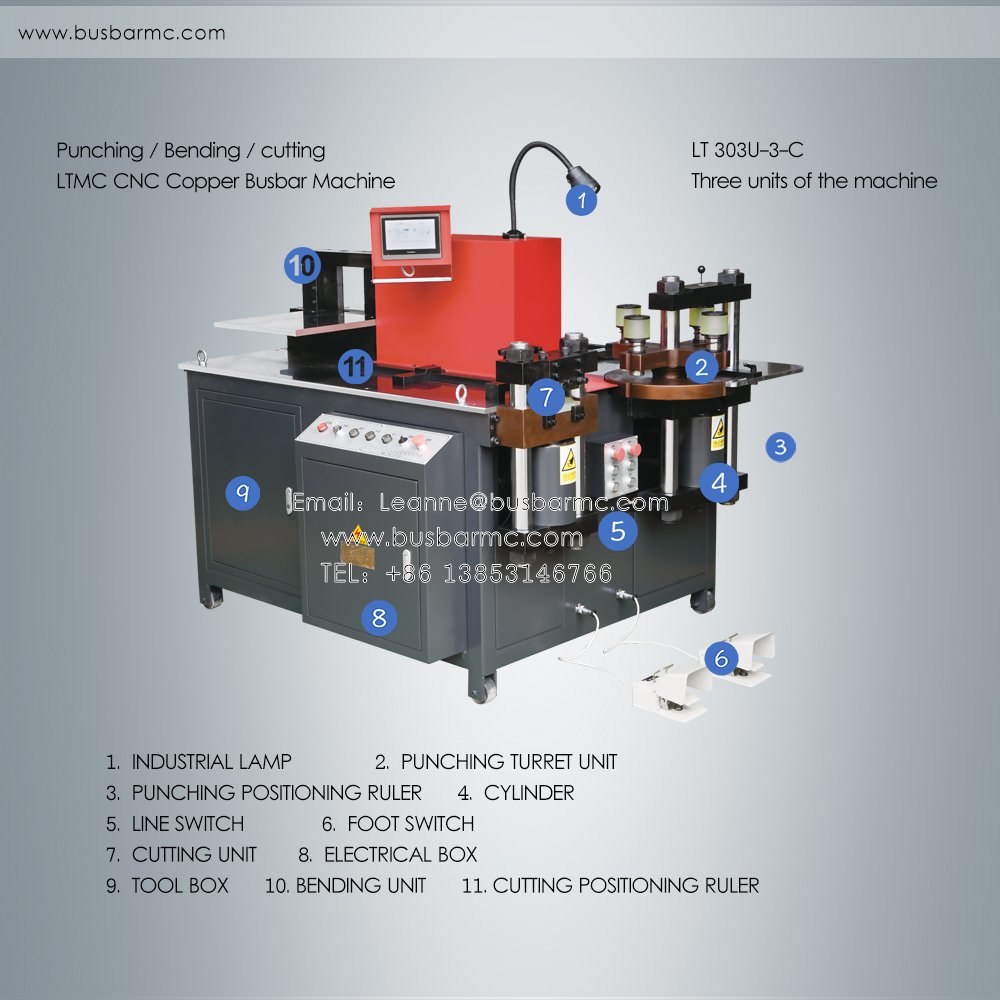

Product Details & Structure:

1. Industrial LED Lamp 2. Turret Punching Unit (Six-Mold) 3. Punching Positioning Ruler 4. Hydraulic Cylinder 5. Limit Switch 6. Foot Switch 7. Shearing/Cutting Unit 8. Electrical Control Box 9. Tool Box 10. Bending Unit 11. Cutting Positioning Ruler

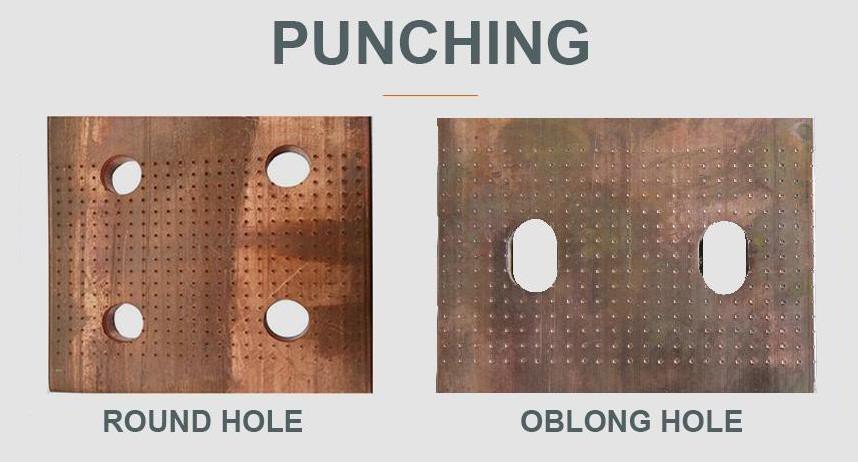

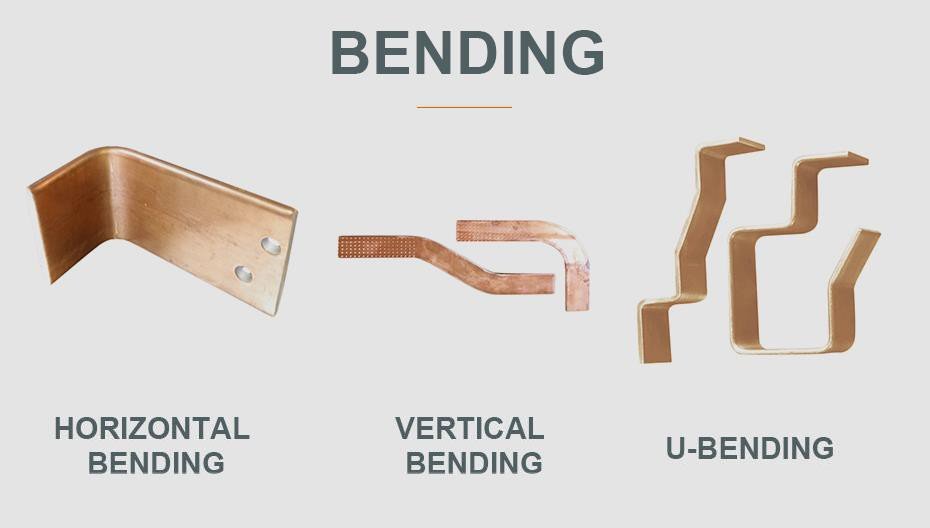

Processing Samples (Copper & Aluminium):

Punching: Capable of punching Round holes and Oblong (Oval) holes with high precision.

Bending: Capable of performing Horizontal Bending (Flat Bend), Vertical Bending, and U-Bending.

Special Functions: With optional molds, the machine can perform Embossing, Twisting, and Cable Connector processing.

Our Factory & Workshop:

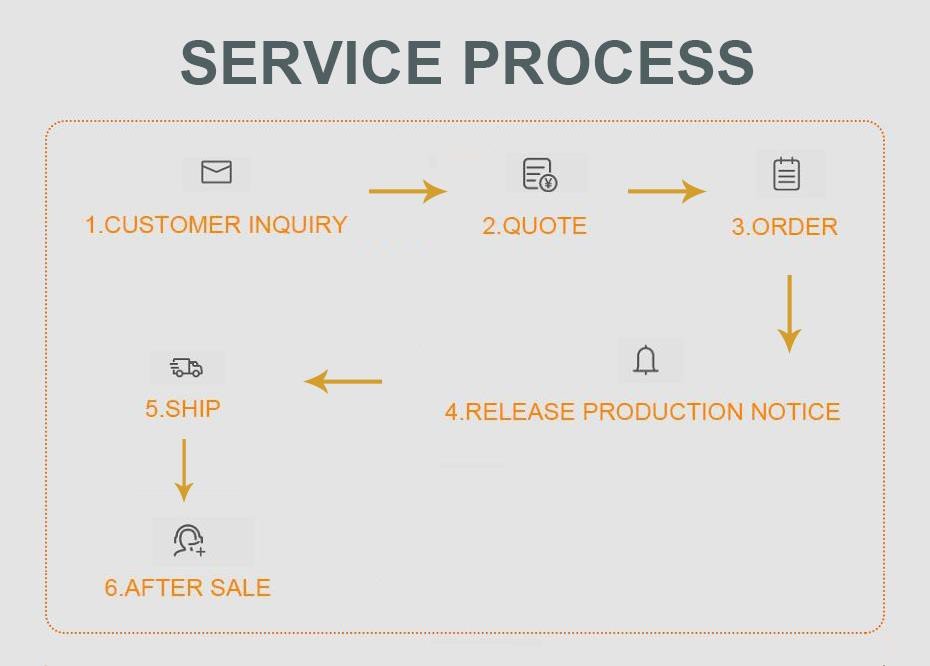

Our Service Process:

Our dedicated after-sales service engineers conduct regular return visits to listen to your valuable feedback and continuously improve product quality for the Indian market.

Package & Delivery:

We use waterproof plastic film wrapped inside and sturdy wooden cases outside, ensuring safe sea freight to Mumbai, Chennai, or Nhava Sheva.

Our Certifications:

The ISO9001 quality assurance system is the foundation of our enterprise development. It is the international standard developed by TC176, ensuring our machines meet global quality benchmarks.

Technical Parameters:

Item | Model | |

303U-3 | 303U-3-C | |

Nominal force (kn) | 300 | 300 |

Punching dia. range (mm) | ф4.3~ф25 | ф4.3~ф25 |

Max.thickness (mm) | 12 | 12 |

Max.width (mm) | 150 | 150 |

Max.shearing thickness (mm) | 12 | 12 |

Max.shearing width (mm) | 150 | 150 |

Max.horizontal bending width (mm) | 150 | 150 |

Max.horizontal bending thickness (mm) | 12 | 12 |

Max.vertical bending size (mm) | 10×100 | 10×100 |

Power (kw) | 1×4KW | 3×4KW |

Table size (mm) | 1650×1050 | 1650×1050 |

Outside dimension (mm) | 1720×1220×1220 | 1720×1220×1220 |

Container size (mm) | 1800×1300×1430 | 1800×1300×1430 |

Total weight (kg) | 1220KG | 1320KG |

Main Features:

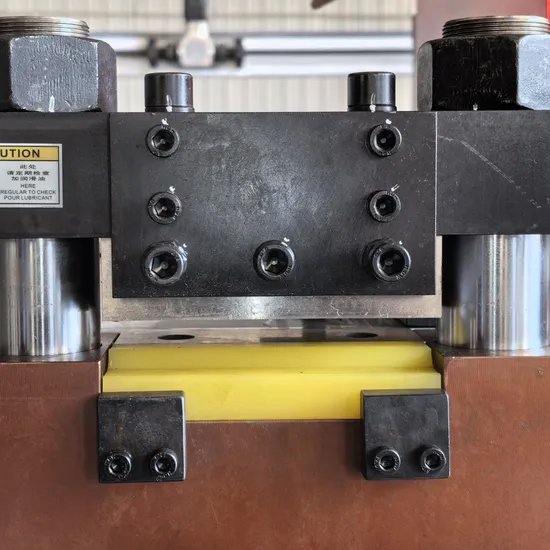

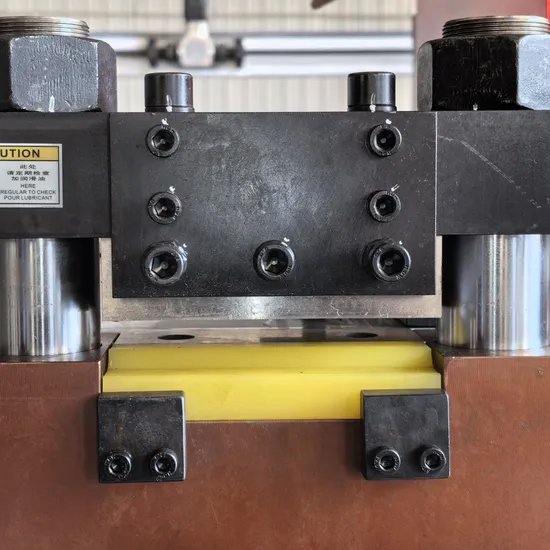

1. Shearing Unit: Adopts vertical processing mode with a sharp flat blade. The cut interface is flat with no waste, no burrs, and no droop, saving material costs.

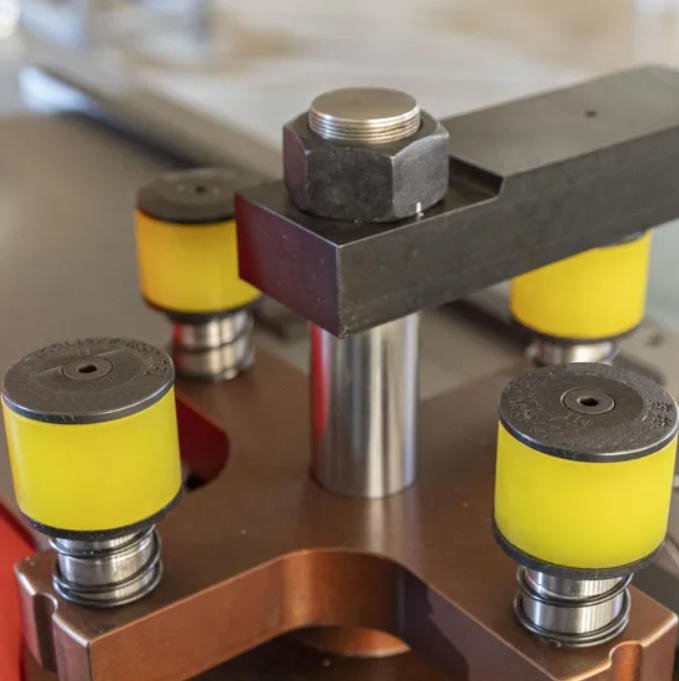

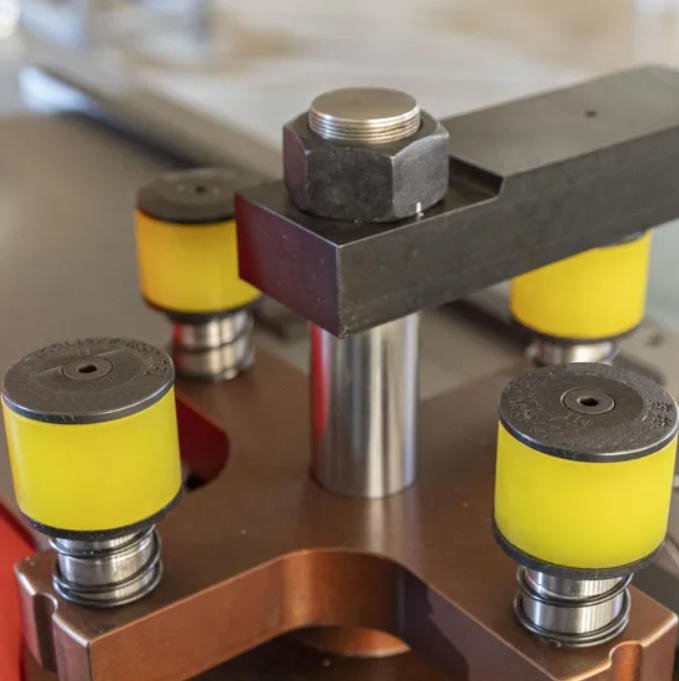

2. Punching Unit: Features a six-mode Turret Turnplate in tooth shape. It provides a good view, eliminates the need to change dies frequently, and ensures simple, efficient operation.

3. Bending Unit: Capable of Flat and Vertical bending. By changing molds, it handles various angles precisely.

4. Multifunction: Achieves Embossing, Flattening, Twisting, and Cable End Crimping by simply changing the respective tools/dies.

5. Mobility: Equipped with four heavy-duty casters, making it easy to move around the workshop or construction site.

6. Customization: We can install different molds or tools according to specific user requirements for special shape processing.

Hot Tags (India): 303U-3-C manual busbar machine price India, 3 in 1 hydraulic busbar processing machine,

Hot Tags: 3 in 1 manual hydraulic busbar machine, copper busbar cutting punching bending machine, busbar bending machine India, aluminium busbar processing machine, switchgear manufacturing machines, busbar machine suppliers China, factory price.

Manual 3-in-1 Busbar Machine Demo Video:

1. What is the main application of the 303U-3-C machine?

The 303U-3-C is a 3-in-1 machine used for Punching, Shearing (Cutting), and Bending Copper and Aluminium busbars. It is widely used in India for manufacturing Electrical Panels, Switchgears, and Distribution Boxes.

2. Can the three units work simultaneously?

Yes. The machine is equipped with three independent motors (3×4kW), allowing the Punching, Cutting, and Bending units to work simultaneously or sequentially, greatly improving efficiency.

3. How is the machine controlled?

It is a manual hydraulic machine controlled via Push Buttons or a Foot Switch. This makes it easy to operate and maintain, ideal for workshops and construction sites.

4. What are the key advantages of this model?

Key features include: Vertical Cutting (No scrap/waste), Turret Punching (No frequent die change), versatile Bending capabilities, and easy mobility with casters.

5. What is the maximum processing capacity?

Max Force: 300 kN; Max Thickness: 12 mm; Max Width: 150 mm; Punching Diameter: ф4.3–ф25 mm.

6. Is it suitable for use at construction sites?

Yes. Its robust design and mobility make it suitable for on-site fabrication of large-scale electric control boxes and transmission projects.

7. How do you ensure safe delivery to India?

The machine is wrapped in waterproof plastic film and secured in a strong wooden crate, ensuring it arrives safely at Indian ports.

8. Does the machine have international certification?

Yes, it complies with ISO9001 quality management standards.

9. Can it perform special processing like twisting?

Yes. By installing different molds, it can perform Embossing, Twisting, Cable Connector Crimping, and special shape bending.

10. Do you provide after-sales support in India?

Yes. We provide technical support and our engineers regularly follow up to ensure customer satisfaction and machine performance.

Manual Busbar Machine Price India, 3 in 1 Busbar Processing Machine, Hydraulic Busbar Bender Puncher Cutter, Copper Busbar Machine Manufacturer, Aluminium Busbar Fabrication Tool

Industry Keywords: 303U-3-C busbar machine, 3 in 1 hydraulic busbar machine, manual busbar processing machine, copper busbar bending machine India, aluminum busbar processing equipment, non-CNC busbar machine, high voltage busbar machine, low voltage panel board machine, portable busbar machine, industrial electrical busbar machine, customizable busbar processing machine, busbar fabrication machine price, multi-function busbar machine, compact busbar machine, hydraulic busbar bending press, busbar cutting machine no burr, busbar punching machine turret type, electrical switchgear machinery, power distribution cabinet tools.