Optimize your Transformer manufacturing with the LTMC 303U-3-C CNC Busbar Processing Machine. This versatile 3-in-1 Hydraulic system delivers high-precision Punching, Cutting, and Bending for Copper & Aluminium busbars. Designed for Indian heavy electrical industries, it ensures efficient mass production with PLC control. Robust, reliable, and easy to operate. Contact us today for the best CNC Busbar Machine Price in India.

Product Description: 303U-3-C Manual Hydraulic Busbar Machine (3-in-1)

Main Features:

1. The Shearing/Cutting Unit adopts double column shearing dies, ensuring stability and a smooth cut without burrs.

2. The Punching Unit features an integral Six-Mode Turnplate (Turret), which ensures the upper and lower molds are absolutely centered, reducing die change time.

3. The Bending Unit adopts a closed bending structure. This design ensures uniform force during horizontal bending and embossing, significantly improving repeat positioning accuracy for mass production of electrical panels.

4. Customized molds or tools can be installed according to user requirements to complete special shape processing like Twisting or Cable End Crimping.

Product Structure Details:

1. CNC TOUCH SCREEN (Optional)

2. INDUSTRIAL LAMP

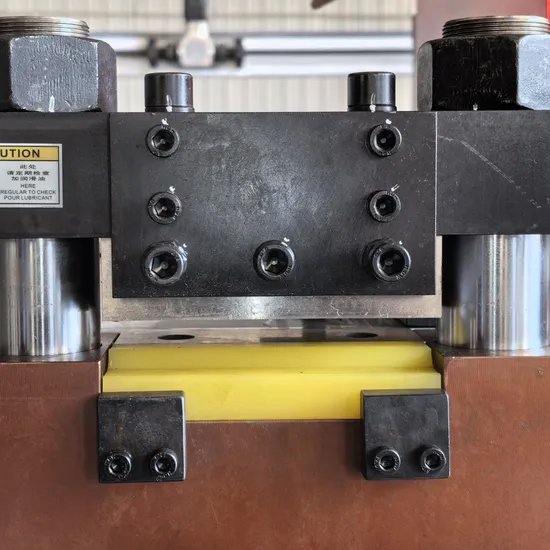

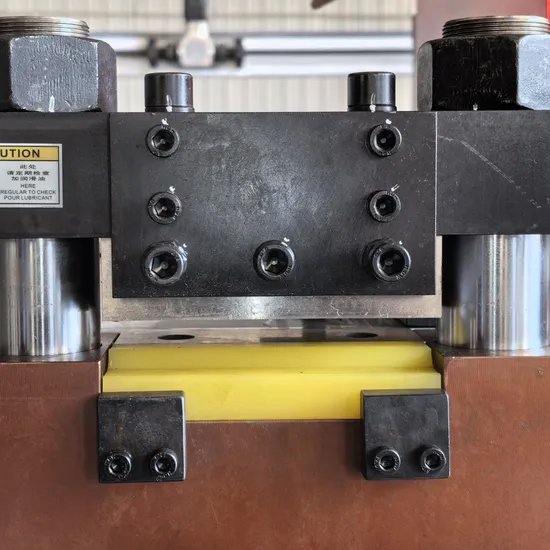

3. PUNCHING TURRET UNIT

4. PUNCHING POSITIONING RULER

5. CYLINDER

6. LINE SWITCH

7. FOOT SWITCH

8. CUTTING UNIT

9. ELECTRICAL BOX

10. TOOL BOX

11. BENDING UNIT

12. CUTTING POSITIONING RULER

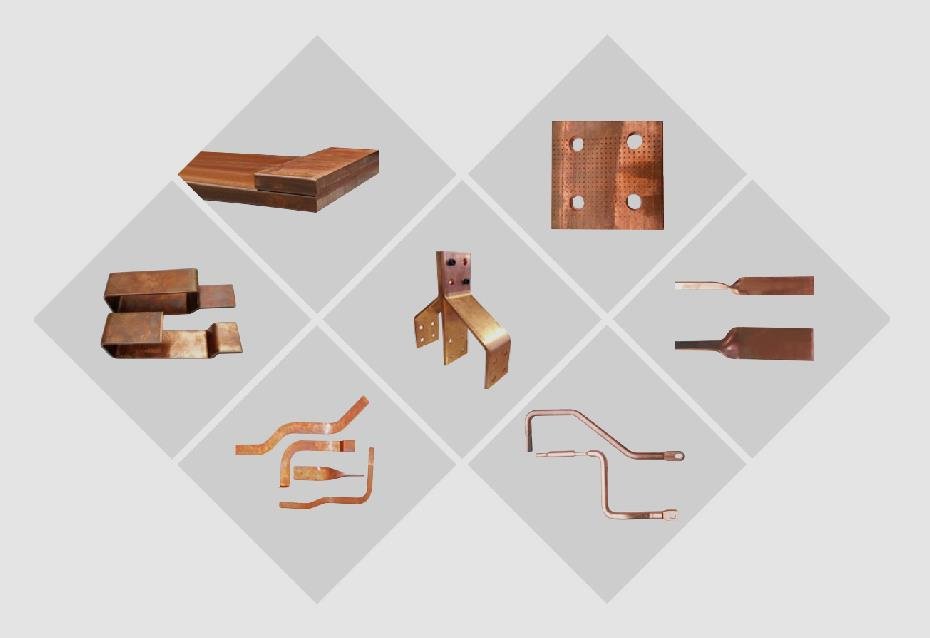

Processing Samples:

The LT-303U-3-C is a versatile 3-function busbar processing machine designed for Copper and Aluminium.

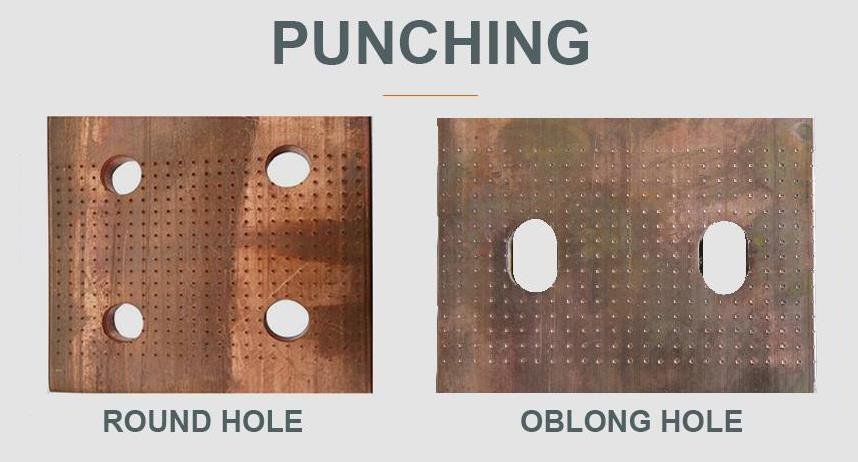

Function 1: Punching

Capable of punching Round holes and Oblong (Oval) holes.

Function 2: Cutting (Shearing)

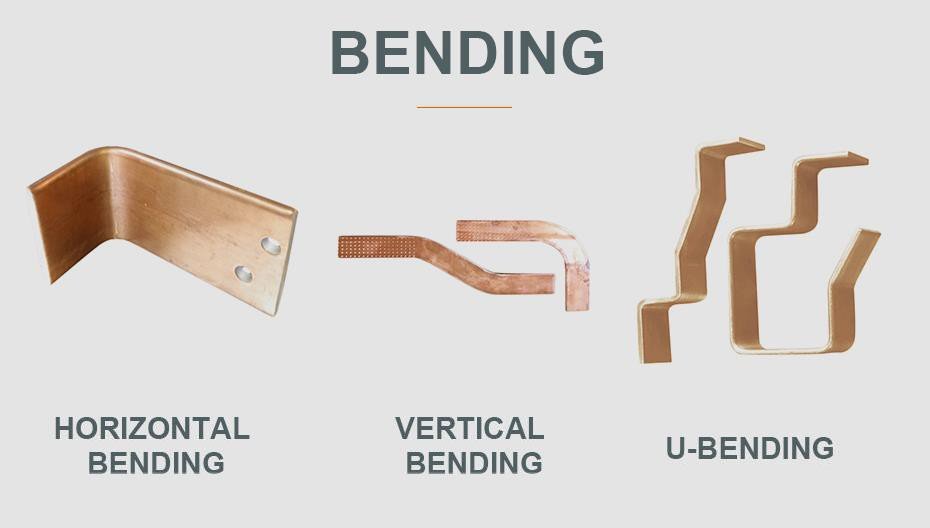

Function 3: Bending

It can perform Vertical Bending, Flat Bending, U-Bending, and Z-Bending by simply changing the molds.

Other Special Functions:

Our Factory:

Our Service:

Our after-sales service engineers conduct regular return visits to listen to your valuable feedback and continuously improve product quality for the Indian market.

Package & Delivery:

We use waterproof plastic film wrapped inside and sturdy wooden cases outside to ensure safe shipping to India.

Our Certifications:

ISO9001:2000 / CE Certified

| Items | Model |

| LT-303U-3-C | |

| Nominal force (kn) | 300 |

Punching dia. range (mm) | ф4.3~ф25 |

Max. thickness (mm) | 12 |

Max. width (mm) | 160 |

| Max. shearing thickness (mm) | 12 |

| Max. shearing width (mm) | 160 |

| Max. horizontal bending width (mm) | 160 |

Max. Horizontal bendind thickness (mm) | 12 |

| Max. vertical bending size (mm) | 10×100 |

Power (kw) | 3×4KW |

| Bending precision (degree) | ±1° |

| Repeat bending precision (degree) | ±0.5° |

First table size (mm) | 1650×1050 |

Second table size (mm) | no |

| Outside dimension (mm) | 1720×1220×1240 |

| Container size(mm) | 1800×1300×1450 |

| Total weight(kg) | 1320KG |

LT Busbar Machine Demo Video:

Q1: What functions does the LT-303U-3-C busbar machine provide?

A: The LT-303U-3-C is a versatile 3-in-1 busbar processing machine. It integrates Punching, Cutting, and Bending functions for Copper and Aluminium busbars. It supports Round/Oblong holes, Shearing, Vertical Bending, Flat Bending, U-Bending, and Z-Bending.

Q2: What is the punching capability?

A: The punching unit uses an integral Six-Mode Turret Turnplate to ensure perfect alignment. It punches holes from Φ4.3 mm to Φ25 mm on busbars up to 12 mm thick and 160 mm wide.

Q3: What are the shearing (cutting) specifications?

A: The cutting unit uses Double-Column Shearing Dies for stability. It provides a clean cut on Copper/Aluminium busbars up to 12mm x 160mm without waste.

Q4: What type of bending structure does it use?

A: It uses a Closed Bending Structure, ensuring uniform force application. This improves precision for horizontal bending and embossing, ideal for mass production.

Q5: Can it use customized molds?

A: Yes. We can provide customized molds for special shapes like Twisting, Embossing, or Cable Connector Crimping based on your drawings.

Q6: What is the bending precision?

A: The machine offers a bending accuracy of ±1° and a repeat precision of ±0.5°.

Q7: What is the power requirement?

A: The machine is equipped with three independent motors (3 × 4 kW). We can customize the voltage (e.g., 415V, 50Hz) for India.

Q8: What after-sales service do you offer in India?

A: We provide comprehensive support including video guides, online troubleshooting, and regular follow-ups. Spare parts like dies and blades can be shipped quickly.

Q9: How is it packaged for export?

A: The machine is wrapped in waterproof plastic film and secured in a robust wooden crate for safe sea transportation to Indian ports.

Q10: Is it certified?

A: Yes, the LT-303U-3-C is certified with ISO9001:2000 and CE standards.

Industry Keywords (India Market):

303U-3-C busbar machine, manual hydraulic busbar machine price India, 3 in 1 busbar processing machine, copper busbar bending machine, aluminium busbar fabrication machine, busbar punching and shearing machine, hydraulic busbar press, non-CNC busbar machine, switchgear manufacturing machines, busbar machine manufacturer China, copper patti machine, heavy duty busbar workstation, busbar forming machine, electrical panel fabrication tools.