Boost your switchgear production efficiency with our Fully Automatic CNC Busbar Processing Machine. This high-speed 3-in-1 system offers simultaneous Punching, Shearing (Cutting), and Bending for Copper & Aluminium busbars. Equipped with advanced Siemens/Panasonic PLC control for maximum precision, it is the ideal solution for Mass Production in Transformer and Electrical Panel industries. Save labour costs and ensure consistent quality. Contact us today to get the best CNC Busbar Machine Price in India.

Fully Automatic CNC Busbar Processing Machine (3-in-1) for Indian Switchgear Industry

Model: 503U-3-C / 303U-3-C | Copper & Aluminium Punching Bending Cutting

Product Overview:

This Fully Automatic CNC Busbar Processing Machine integrates three independent stations: Punching, Shearing (Cutting), and Bending. Designed for high-volume Indian panel builders, it features three independent hydraulic systems, allowing all three units to work simultaneously without loss of power.

The machine achieves Automatic Positioning via a precision Servo Motor, PLC Control (Siemens/Panasonic), and Touch Screen interface, ensuring maximum efficiency for Copper and Aluminium busbar fabrication.

Main Features for Mass Production:

(1) Auto-Cutting Unit: The cutting length is automatically controlled by the Servo system. The shearing interface is completely flat, ensuring no waste (scrap-free), no burrs, and no droop, saving expensive Copper material.

(2) Auto-Punching Unit: No need for marking! The Servo motor automatically locates punching coordinates (X/Y axis). It supports continuous punching, mixed aperture sizes, and template library selection, making it ideal for standard Switchgear panels.

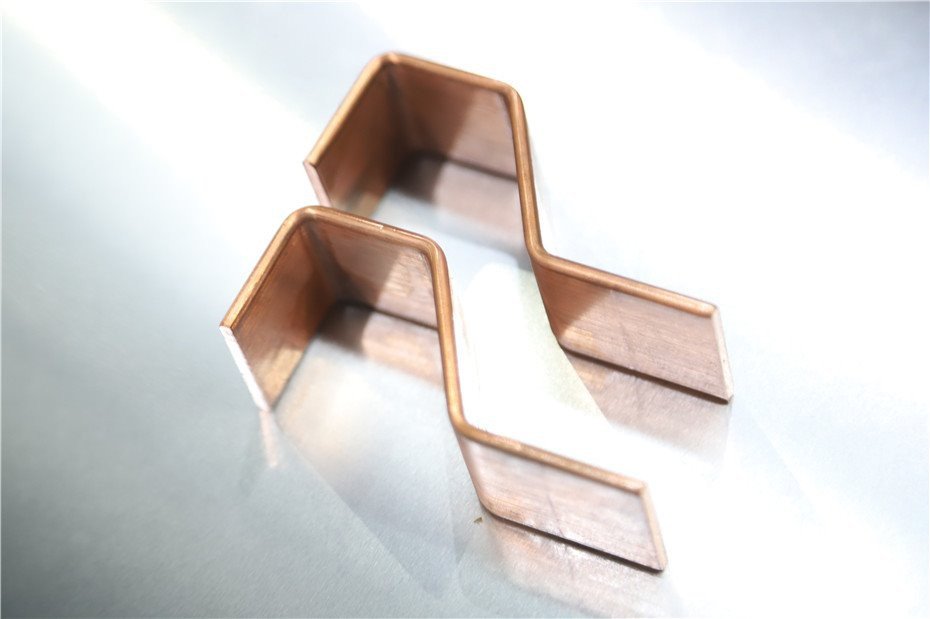

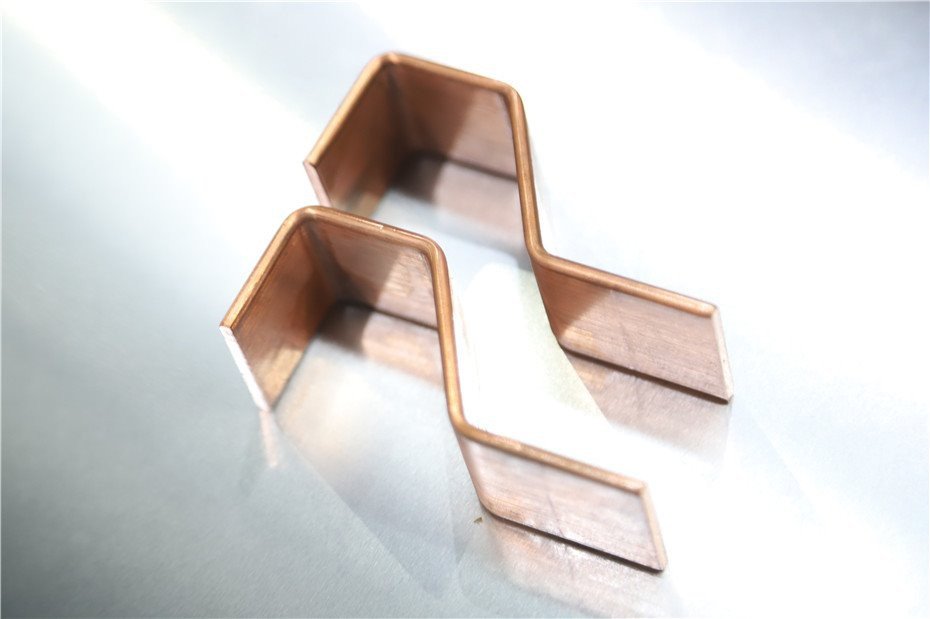

(3) CNC Bending Unit: The system automatically calculates the unrolling length (stretch length) of the Copper/Aluminium busbar. High-precision ball screws control the bending position. It supports multi-segment (Z-bend) and multi-angle continuous bending with built-in templates.

Processing Units Display:

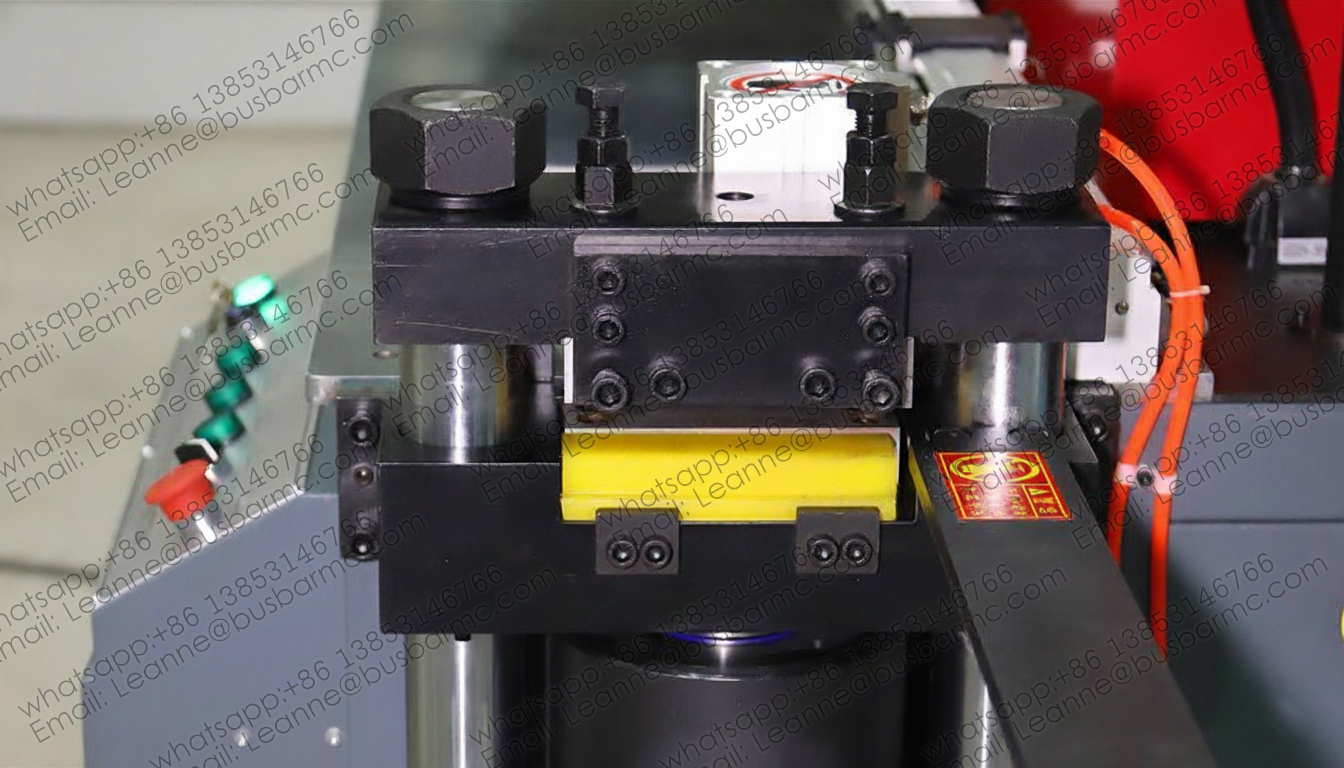

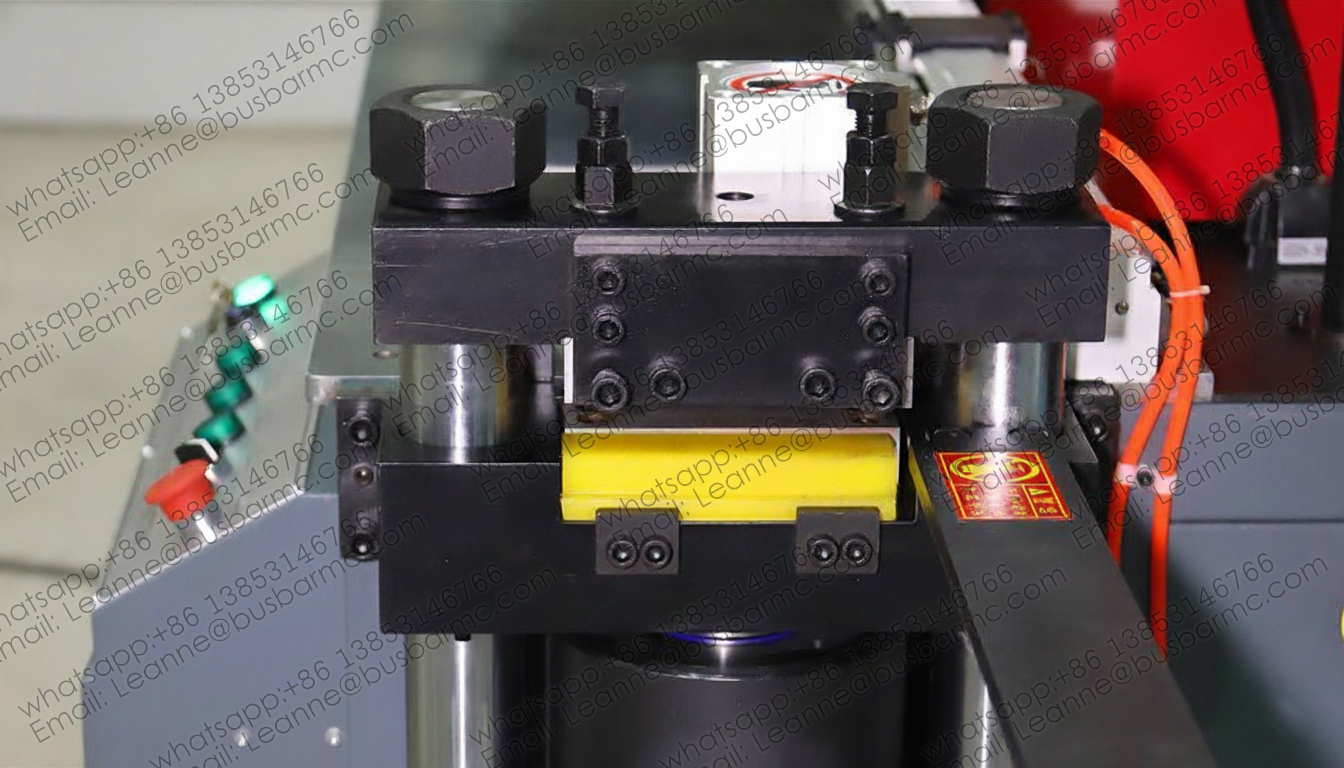

CNC Cutting Unit (Scrap-free):

CNC Punching Unit (Auto Positioning):

CNC Bending Unit (High Precision):

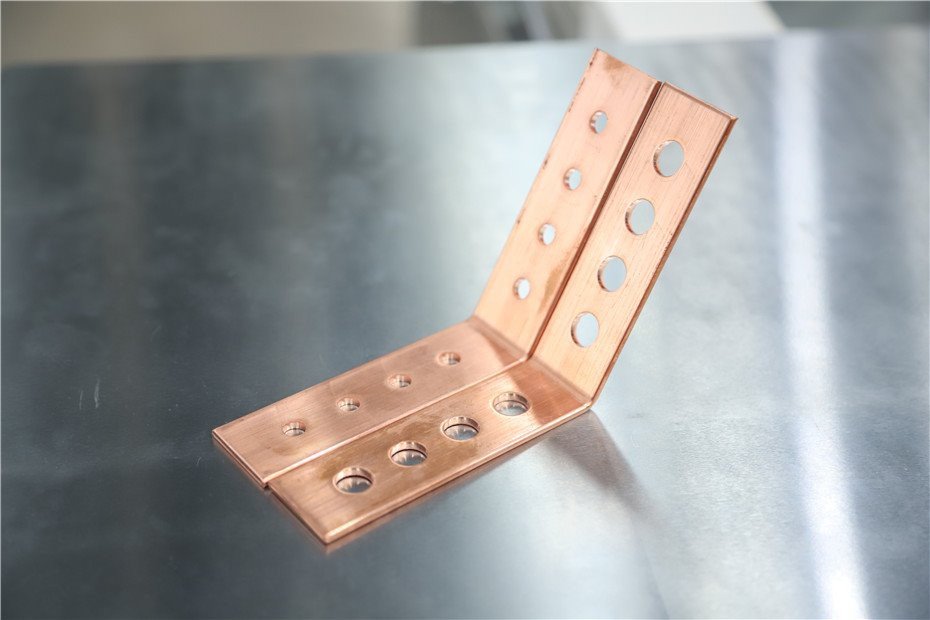

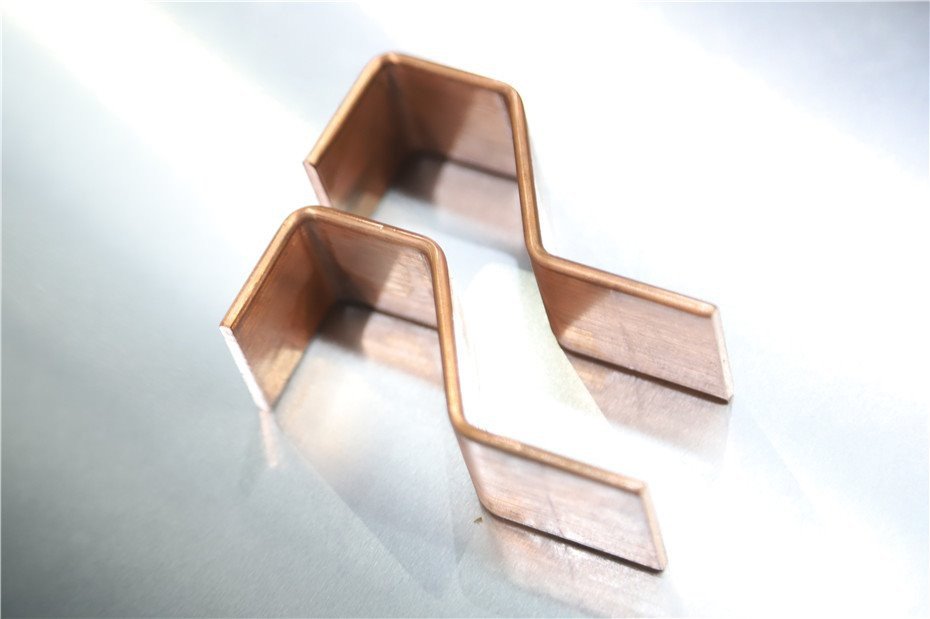

Processing Samples (Copper & Aluminium):

Technical Parameters:

| Item | Model | ||

303U-3-C | 503U-3-C | 803U-3-C | |

Nominal force (kn) | 300 | 500 | 800 |

Punching dia. range (mm) | Φ4.3~Φ25 | Φ4.3~Φ30 | Φ4.3~Φ34 |

Max. thickness (mm) | 12 | 16 | 20 |

Max. width (mm) | 160 | 200 | 250 |

Number of servo axes | 4 | 4 | 4 |

Power (kw) | 3×4kw | 3×5.5kw | 3×5.5kw |

Bending precision | ±1° | ±1° | ±1° |

Repeat bending precision | ±0.5° | ±0.5° | ±0.5° |

Outside dimension (mm) | 1850×1650×1340 | 2015×1815×1420 | 2060×1660×1650 |

Total weight (kg) | 1500 | 1900 | 2100 |

CNC Busbar Machine Demo Video (Simultaneous Operation):

Q1: What are the main functions of this Fully Automatic Machine?

A1: It integrates CNC Punching, Auto-Shearing, and CNC Bending. All three units operate simultaneously with independent hydraulic systems, drastically reducing production time for Switchgear manufacturing.

Q2: Does it require manual marking for punching?

A2: No. The machine uses a Servo Motor to automatically position the copper busbar for punching coordinates. It supports continuous punching without any manual marking proofing.

Q3: How accurate is the bending angle?

A3: The system uses a high-precision PLC and screw guides to control bending. It offers a bending precision of ±1° and repeat precision of ±0.5°, perfect for high-quality Panel Boards.

Q4: What is the maximum capacity (Thickness x Width)?

A4:

- 303U-3-C: Max 12mm x 160mm

- 503U-3-C: Max 16mm x 200mm

- 803U-3-C: Max 20mm x 250mm (Heavy Duty)

Q5: Can it process Aluminium Busbars (Aluminium Flats)?

A5: Yes, it is fully compatible with both Copper (Cu) and Aluminium (Al) busbars used in Transformers and Power Distribution.

Q6: What is the delivery time to Indian ports (Nhava Sheva/Chennai)?

A6: Production time is 7-25 days. Shipping to India typically takes 3-4 weeks. We export regularly to India and can assist with customs documentation.

Q7: What certificates do you hold?

A7: We hold ISO9001:2000 and CE certifications, ensuring international quality standards.

Fully Automatic Busbar Machine Price India, CNC Copper Busbar Punching Cutting Machine, Automatic Busbar Bending Machine, 3 in 1 Busbar Processing Machine CNC, Busbar Machine for Panel Builders

Industry Keywords: Fully automatic busbar machine, CNC busbar processing machine India, 3 in 1 busbar machine automatic, CNC copper busbar punching cutting bending machine, aluminium busbar fabrication machine, auto busbar production line, CNC copper patti machine, hydraulic busbar machine price in India, switchgear manufacturing equipment, Siemens PLC busbar machine, heavy duty busbar processor, automatic busbar bending machine with servo, busbar punching machine auto positioning, electrical panel manufacturing machinery, high speed busbar machine.