Optimize your Transformer production with the 803U-3-C Automatic CNC Busbar Processing Machine. This heavy-duty 3-in-1 Hydraulic system offers precise Punching, Cutting, and Bending for Copper & Aluminium busbars. Featuring Siemens PLC for high accuracy, it is perfect for Power & Distribution Transformer manufacturers requiring mass production. Contact us today for the best CNC Busbar Machine Price in India.

Automatic CNC Busbar Processing Machine (803U-3-C) for Transformer Manufacturing

3-in-1 Hydraulic Copper & Aluminium Busbar Machine - India

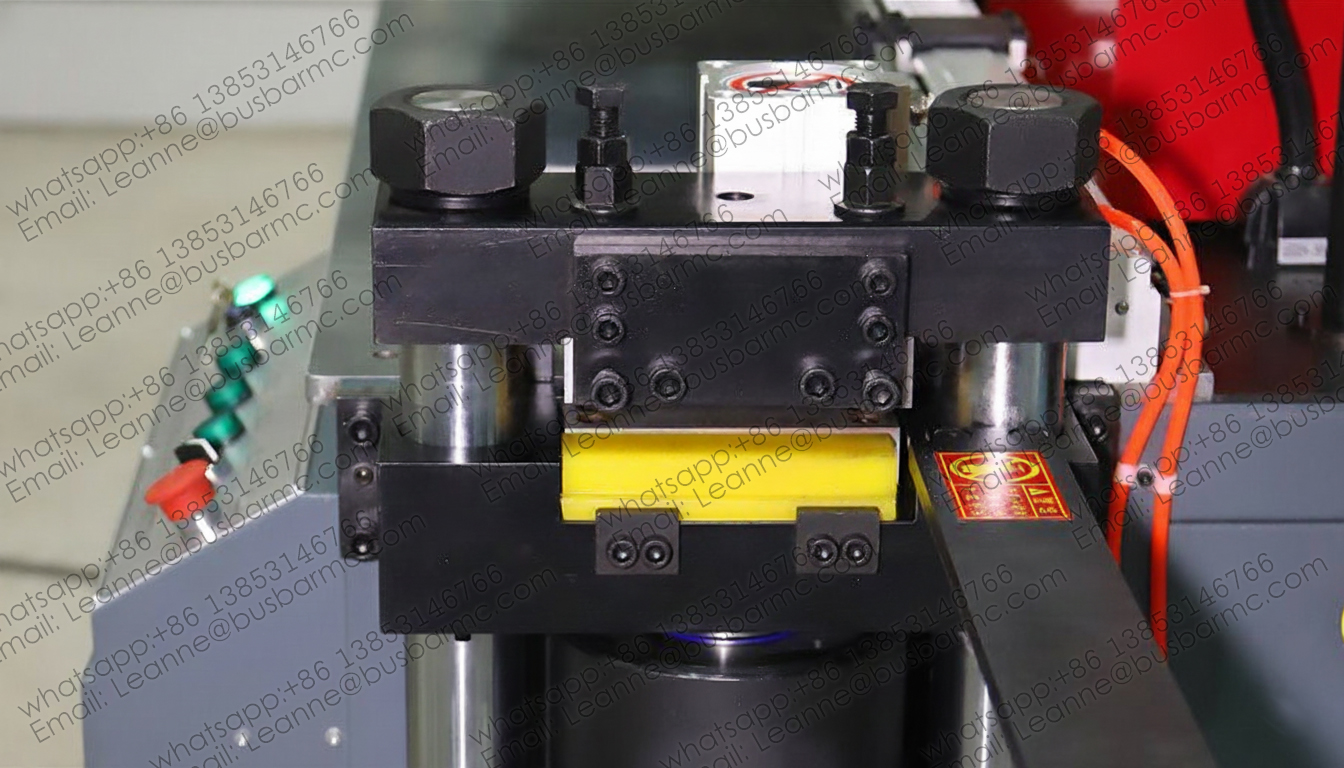

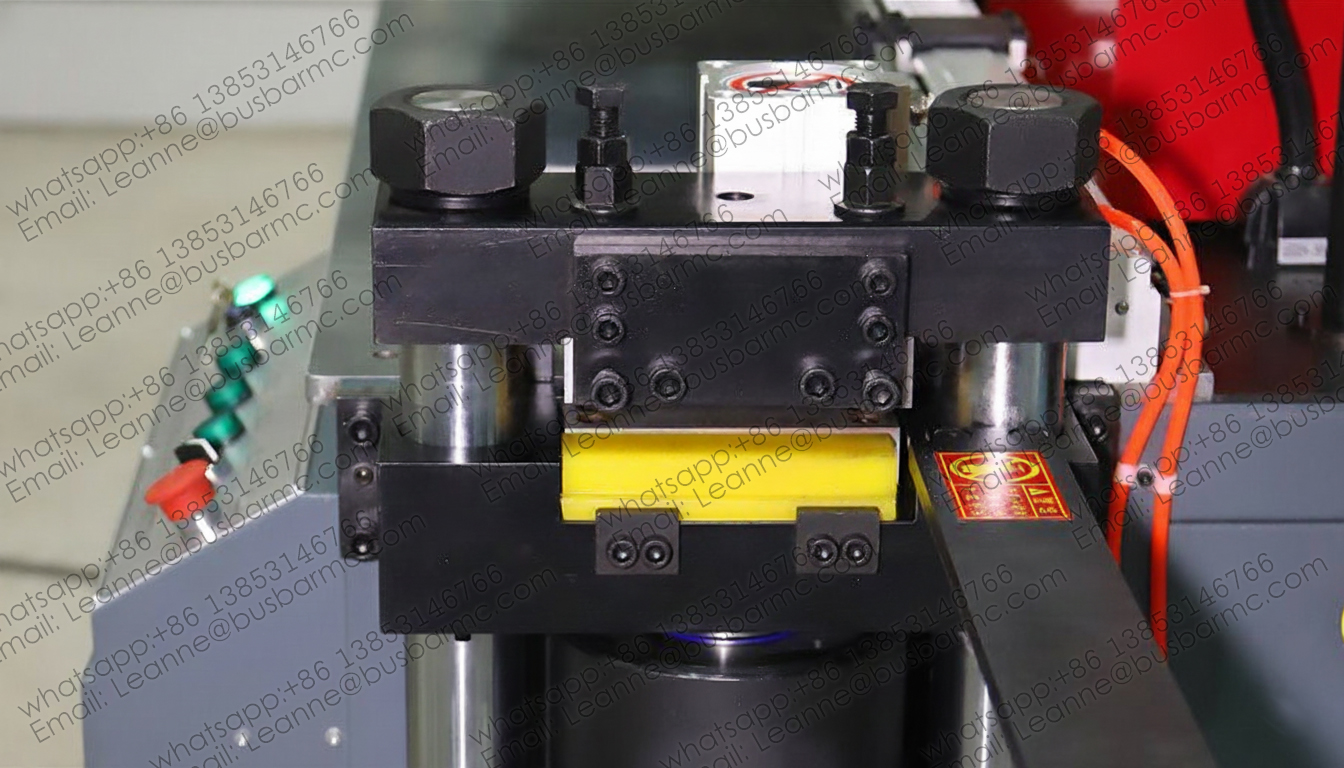

This series of CNC Busbar Processing Machinery (803U-3-C) features three independent processing units: Punching, Shearing (Cutting), and Bending.

Designed for Indian Transformer Manufacturers and Switchgear Panel Builders, the three units can operate simultaneously or sequentially. This significantly reduces processing time and boosts production efficiency for heavy-duty Copper and Aluminium busbars (Copper Patti). The Bending Unit adopts a premium German Siemens PLC control system for high precision.

Technical Parameters:

Items | Model | ||

303U-3-C | 503U-3-C | 803U-3-C | |

Nominal force (kn) | 300 | 500 | 800 |

Punching dia. range (mm) | ф4.3~ф25 | ф4.3~ф30 | ф4.3~ф34 |

Max. thickness (mm) | 12 | 16 | 20 |

Max. width (mm) | 150 | 200 | 250 |

Max. shearing thickness (mm) | 12 | 16 | 20 |

Max. shearing width (mm) | 150 | 200 | 250 |

Max. horizontal bending width (mm) | 150 | 200 | 250 |

Max. Horizontal bendind thickness (mm) | 12 | 16 | 20 |

Max. vertical bending size (mm) | 10×100 | 12×120 | 12×120 |

Power (kw) | 3×4KW | 3×5.5KW | 3×5.5KW |

Bending precision (degree) | ±1° | ±1° | ±1° |

Repeat bending precision (degree) | ±0.5° | ±0.5° | ±0.5° |

First table size (mm) | 1750×1250 | 1920×1385 | 1920×1385 |

Second table size (mm) | 985×500 | 985×500 | 985×500 |

Outside dimension (mm) | 1780×1400×1300 | 1950×1560×1390 | 1950×1560×1450 |

Container size(mm) | 1870×1480×1520 | 2060×1660×1650 | 2060×1660×1650 |

Total weight(kg) | 1400KG | 1700KG | 2100KG |

Product Details & Features:

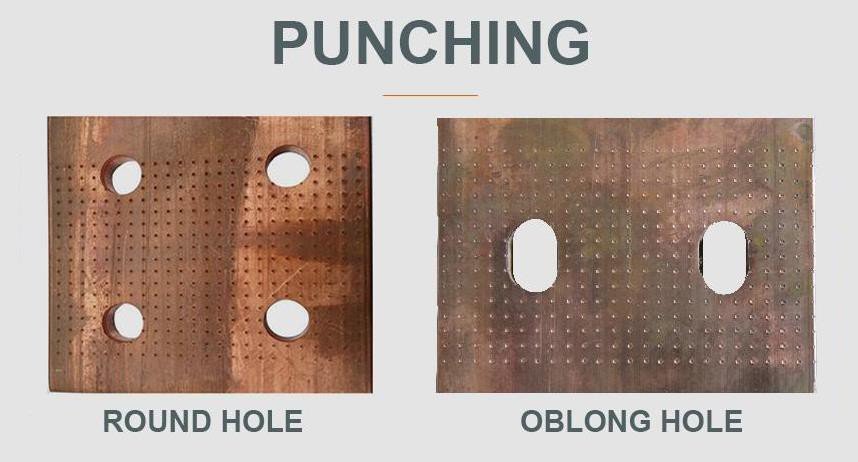

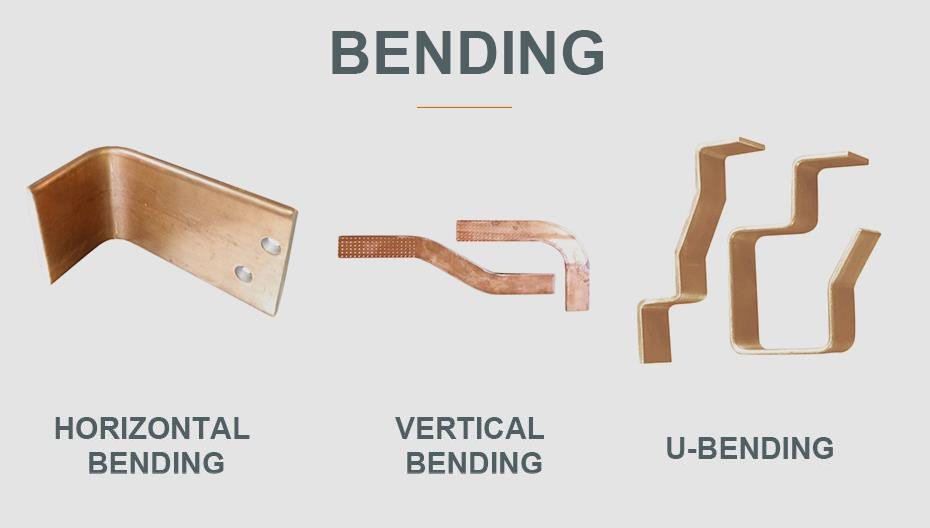

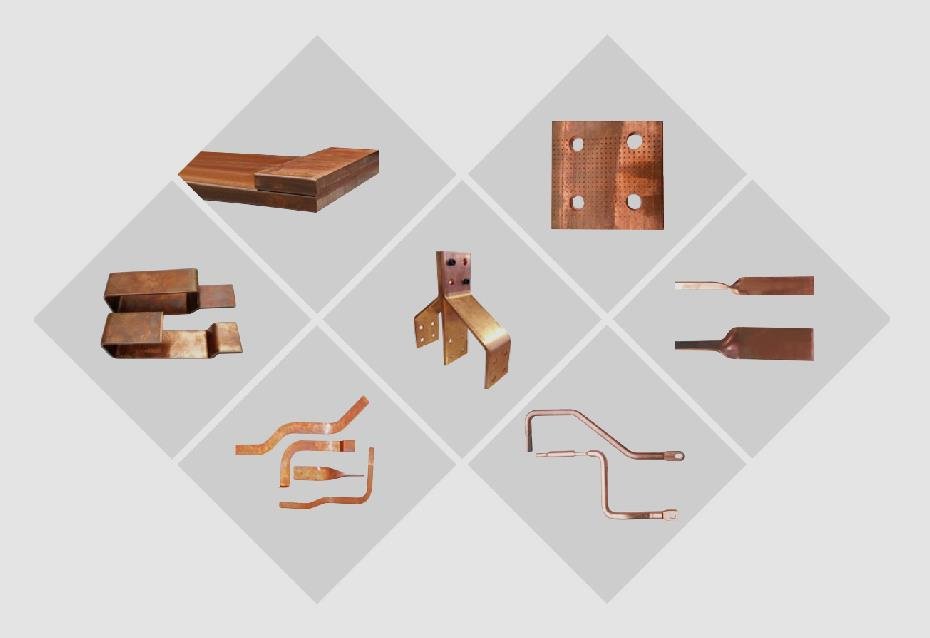

Processing Samples (Copper & Aluminium):

The main function is processing Copper and Aluminium busbars (Copper Patti) in various specifications. Using the respective operation units, it can quickly and easily perform: Shearing/Cutting, Punching (Circular and Oblong holes), Flat/Horizontal Bending, Vertical Bending, U-bending, Embossing, Flat Pressing, Twisting, and Cable Connector processing.

Our Factory:

LTMC Company, founded in 2005, is a high-tech enterprise specializing in R&D, design, and manufacture of electric power equipment and automation CNC equipment. We supply machines to top Indian electrical companies.

Our Service Process for India:

1. Customer Inquiry -> 2. Quote (INR/USD) -> 3. Order -> 4. Production -> 5. Shipping (to Nhava Sheva/Chennai) -> 6. After-sales Service (Video Support/Spare Parts).

Our service engineers conduct regular follow-up visits to ensure your machine runs smoothly for years.

Package & Delivery:

We use waterproof plastic film wrapped inside and sturdy wooden cases outside to ensure safe sea freight to India.

Our Certifications:

Hot Tags (India): 803U-3-C CNC busbar machine price India, 3 in 1 busbar machine for transformers, busbar bending machine, busbar punching machine, busbar cutting machine, copper busbar bending machine, CNC bending machine, CNC punching machine, bending machine, busbar machine, copper busbar machine, cutter machine, machine bending, China, suppliers, manufacturers, factory, price.

CNC Busbar Machine Demo Video:

Q1: Is the 803U-3-C suitable for Transformer Manufacturing?

A1: Yes, absolutely. The 803U-3-C is a heavy-duty CNC machine designed for mass production. It provides high precision for copper busbars used in Distribution and Power Transformers, as well as Switchgear panels.

Q2: Can the three units work simultaneously?

A2: Yes. The Punching, Cutting, and Bending units operate independently with separate hydraulic systems, allowing simultaneous operation to maximize production speed.

Q3: What control system is used for bending?

A3: The Bending Unit is controlled by a genuine German Siemens PLC system, ensuring bending accuracy of ±1° and repeat precision of ±0.5°.

Q4: What voltage does the machine require in India?

A4: We customize the motor voltage to match Indian industrial standards, typically 415V, 50Hz, 3-Phase.

Q5: Can it process Aluminium busbars?

A5: Yes, it is suitable for processing both Copper (Cu) and Aluminium (Al) busbars of various specifications up to 20mm thickness (depending on the model).

Q6: How do you provide service in India?

A6: We offer comprehensive after-sales support including video installation guides, online troubleshooting, and fast dispatch of spare parts like punching dies and blades.

Q7: What is the delivery time to Indian ports?

A7: Production usually takes 15-20 days. Shipping time to ports like Nhava Sheva or Chennai depends on the shipping line, typically around 3-4 weeks.

Industry Keywords (India Market):

CNC busbar processing machine India, 803U-3-C busbar machine, 3 in 1 busbar machine for transformer, automatic busbar bending machine, copper busbar punching cutting bending machine, aluminium busbar fabrication machine, hydraulic busbar machine price in India, heavy duty busbar machine, transformer busbar processing, automatic busbar cutter puncher bender, Siemens PLC busbar machine, busbar machine manufacturer China, copper patti machine, switchgear manufacturing machines.