Looking for a Heavy Duty CNC Busbar Machine in India? Our Model 503U-3-C is designed for high-capacity processing of Copper & Aluminium busbars up to 16mm x 200mm. This fully Automatic 3-in-1 system features independent stations for Punching, Shearing, and Bending, ensuring high efficiency for LT/HT Switchgear panels. Equipped with Siemens/Panasonic PLC for precision control. Contact us today to get the best Heavy Duty Busbar Machine Price in India.

503U-3-C Heavy Duty Hydraulic Busbar Processing Machine (16mm x 200mm)

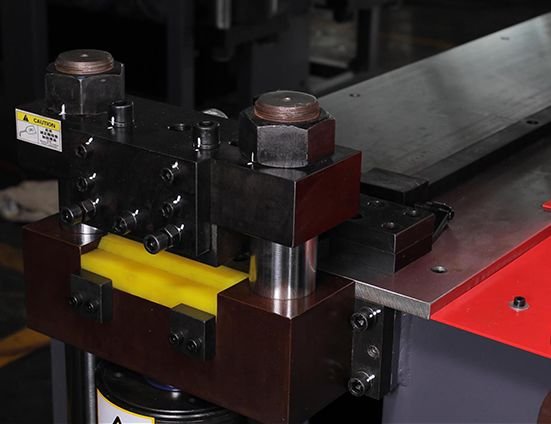

1.Main picture:

This heavy-duty series 503U-3-C Hydraulic Busbar Processing Machine (16mm x 200mm capacity) features three independent units: Punching, Shearing (Cutting), and Bending. It is specially designed for Indian panel builders to shorten processing time and improve production efficiency for heavy copper and aluminium busbars.

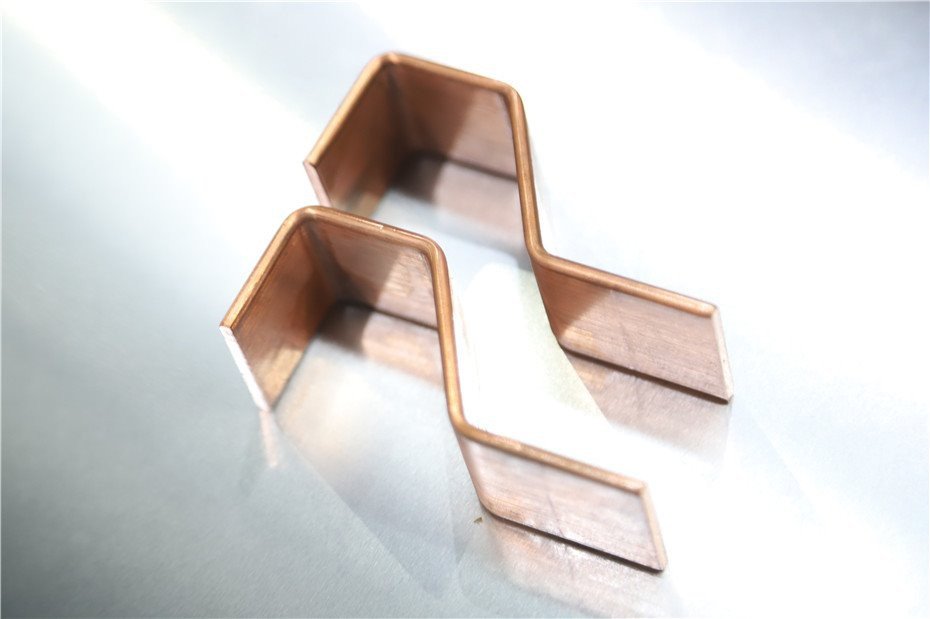

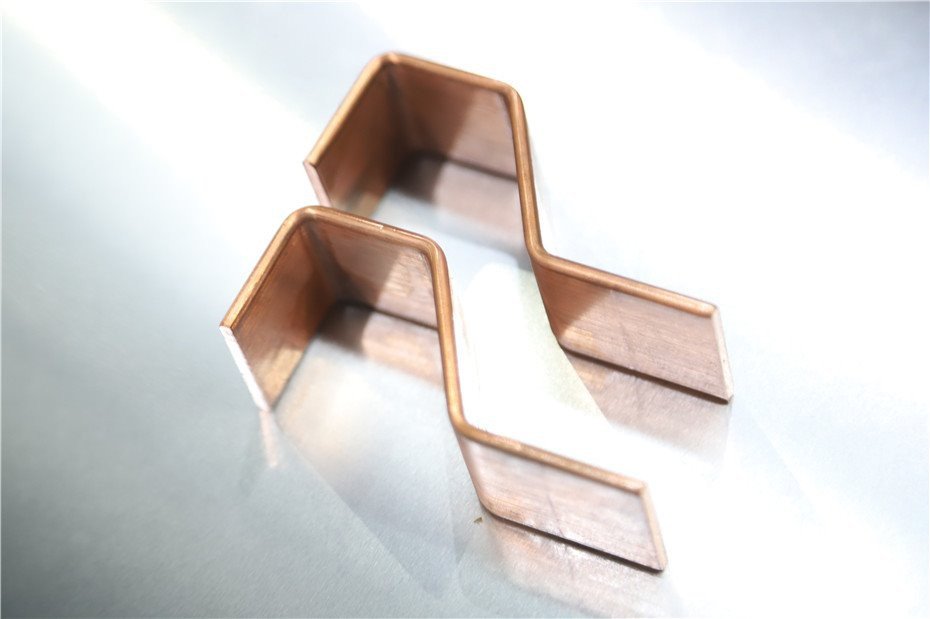

The Bending Unit uses an imported PLC control system (Siemens/Panasonic), ensuring high precision and stable performance. It is used to process copper and aluminium busbars of different specifications commonly found in HT/LT panels. By switching relative operation units, it can quickly perform all kinds of processing such as shearing, punching (circular hole and oblong hole), flat/Vertical bending, and knurling. By changing different molds, it can also perform special processing like Flat Press, Embossing, Cable Connector Process, twisting, and cutting.

2.Three working units (3-in-1 System):

1) Punching Unit:

Capable of punching round and oblong holes on thick busbars (up to 16mm).

2) Shearing / Cutting Unit:

Provides a sharp cut with no waste (scrap-free), ideal for saving copper material costs.

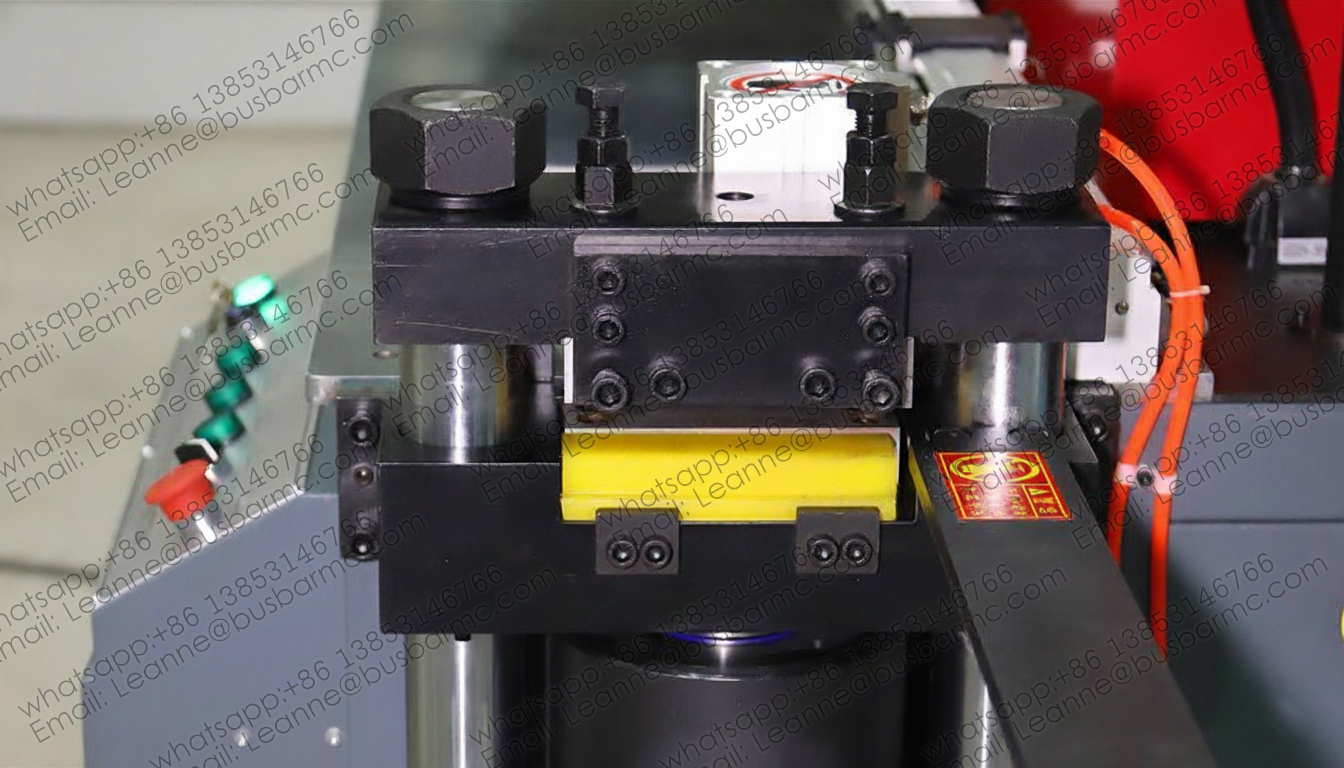

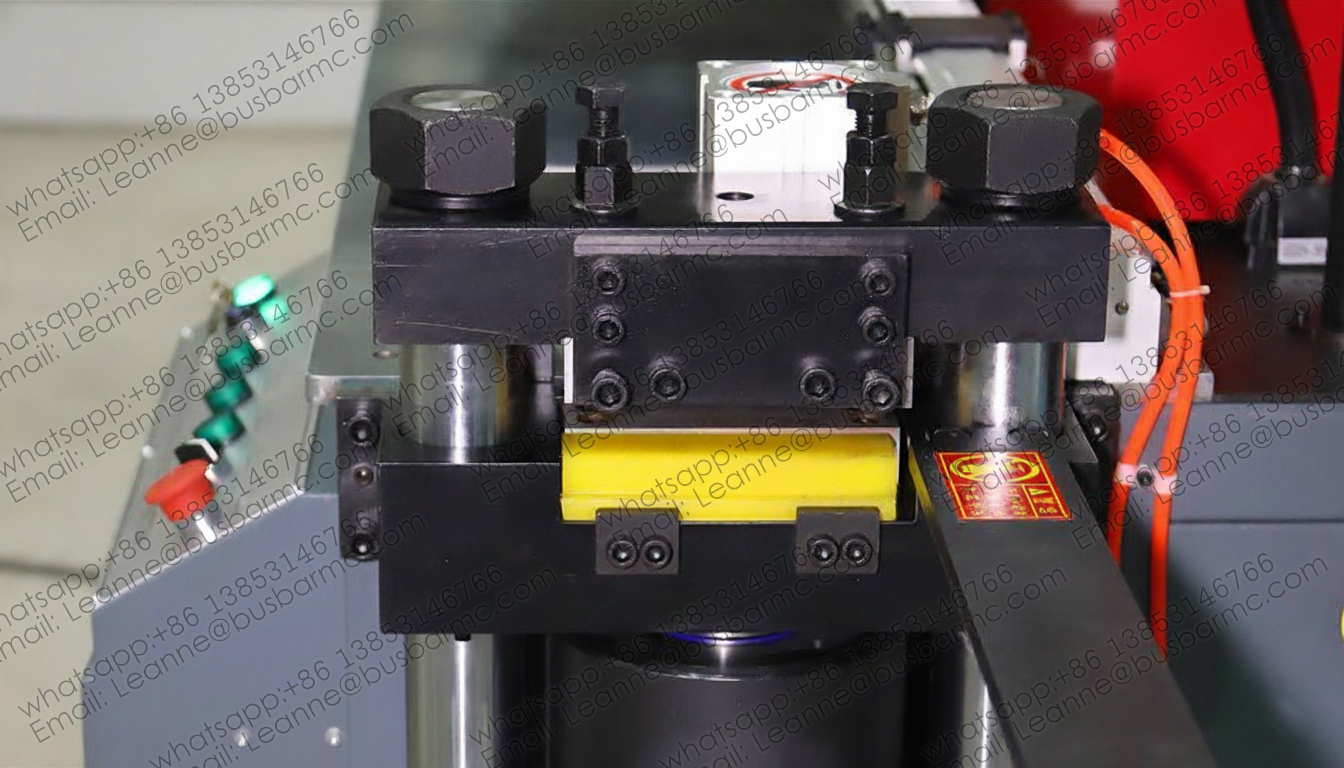

3) Bending Unit:

PLC controlled for precise angle bending (L-bend, Z-bend, U-bend).

3.Packing and Shipment (Export Standard):

1) Firstly, the machine is packed with a plastic moisture-proof sheet.

2) Secondly, the machine is packed in a sturdy wooden case suitable for sea transport to India (Mumbai/Chennai/Nhava Sheva).

4.Service & Support:

24-hour free hotline waiting for you once you have bought our machine.

We will try our best to solve your problems by video call (WhatsApp/Zoom). Quality is our brand promise. We aim to be your best partner in India.

E-mail: Leanne@busbarmc.com

Whatsapp: +8613853146766

Skype: Leanne.Li88

www.busbarmc.com

Hot Tags (India): 503U-3-C CNC busbar processing machine 16mm 200mm, heavy duty busbar machine price India,

Hot Tags: cnc busbar machine, 3 in 1 busbar machine, busbar bending machine, busbar punching machine, busbar cutting machine, copper busbar bending machine, cnc bending machine, cnc punching machine, bending machine, busbar machine, copper busbar machine, cutter machine, machine bending, China, suppliers, manufacturers, factory, price, busbar machine for HT panels, busbar bending machine manufacturers in India.

Heavy Duty Busbar Machine Demo Video:

1. What is the main capacity of the 503U-3-C busbar processing machine?

The 503U-3-C is a Heavy Duty machine designed for processing large copper and aluminium busbars up to 16mm thickness and 200mm width, integrating Punching, Shearing, and Bending functions.

2. What materials are suitable for this machine?

It is suitable for both Copper and Aluminium busbars commonly used in high-power electrical applications like HT Panels and Transformers.

3. Does the bending unit use a PLC control system?

Yes, the bending unit features an imported PLC control system (Siemens/Panasonic) to ensure high bending accuracy (±1°) and consistent results for mass production.

4. What types of punching dies are available?

Standard dies include circular and oblong (oval) holes. We can also provide custom dies for square holes or special embossing as per Indian standards.

5. Can the machine perform Embossing or Flat Pressing?

Yes, by changing the mold tools, the machine can perform specialized functions like Embossing, Flat Pressing, Knurling, and Cable Connector processing.

6. What is the advantage of the 3-unit structure?

The three units (Punch, Cut, Bend) can operate independently and simultaneously. This significantly reduces processing time compared to single-station machines.

7. How is the machine packed for export to India?

The machine is wrapped in a waterproof plastic sheet and secured in a robust wooden crate to prevent damage during sea freight to Indian ports.

8. What voltage options are available for India?

We can customize the motor voltage to match the Indian standard: 415V, 50Hz, 3-Phase (or other specifications as requested).

9. Is it easy to change the molds/dies?

Yes, the system is designed for quick mold changes for Punching, Shearing, and Bending, minimizing downtime.

10. What industries use this heavy-duty machine?

It is widely used in High Tension (HT) Switchgear manufacturing, Power Transformers, Heavy Electrical Engineering, and Busduct systems.

11. How can I get the price and spare parts?

Contact us via WhatsApp or Email for the Best 503U-3-C Machine Price in India. We also stock standard spare parts (punches/dies) for quick delivery.

Heavy Duty Busbar Machine Price India, 16mm Busbar Bending Machine, CNC Copper Busbar Machine 200mm, Hydraulic Busbar Punching Cutting Machine, 3 in 1 Busbar Machine Manufacturer

Industry Keywords: 503U-3-C busbar processing machine, 3-in-1 hydraulic busbar machine India, copper aluminium busbar punching shearing bending machine, heavy duty busbar fabrication equipment, industrial busbar processing machine 16x200mm, busbar punching cutting bending machine automatic, multifunction busbar machine for switchgear, copper busbar processing equipment, aluminium busbar processing machine, hydraulic busbar bending unit 200mm, high-precision busbar punching machine, heavy-duty copper bar cutting machine, electrical panel busbar fabrication machine, switchgear busbar processing equipment, workshop busbar fabrication machine, PLC-controlled busbar bending system, copper bar forming and bending machine, oblong and round hole punching busbar machine, flat and vertical busbar bending equipment, three-station hydraulic busbar machine price, busbar punching press machine, hydraulic copper bar fabrication system, power distribution busbar processing machine, compact hydraulic busbar workstation, electrical industry busbar fabrication machine.